In our last issue we looked at the basics of valve lash. We examined a couple of ways to accomplish the job, ranging from the easy-peasy “Exhaust Opening/Intake Closing” (“EO-IC”) method to the more time consuming OEM method. In either case, it’s not a difficult task, but you have to be reasonably accurate.

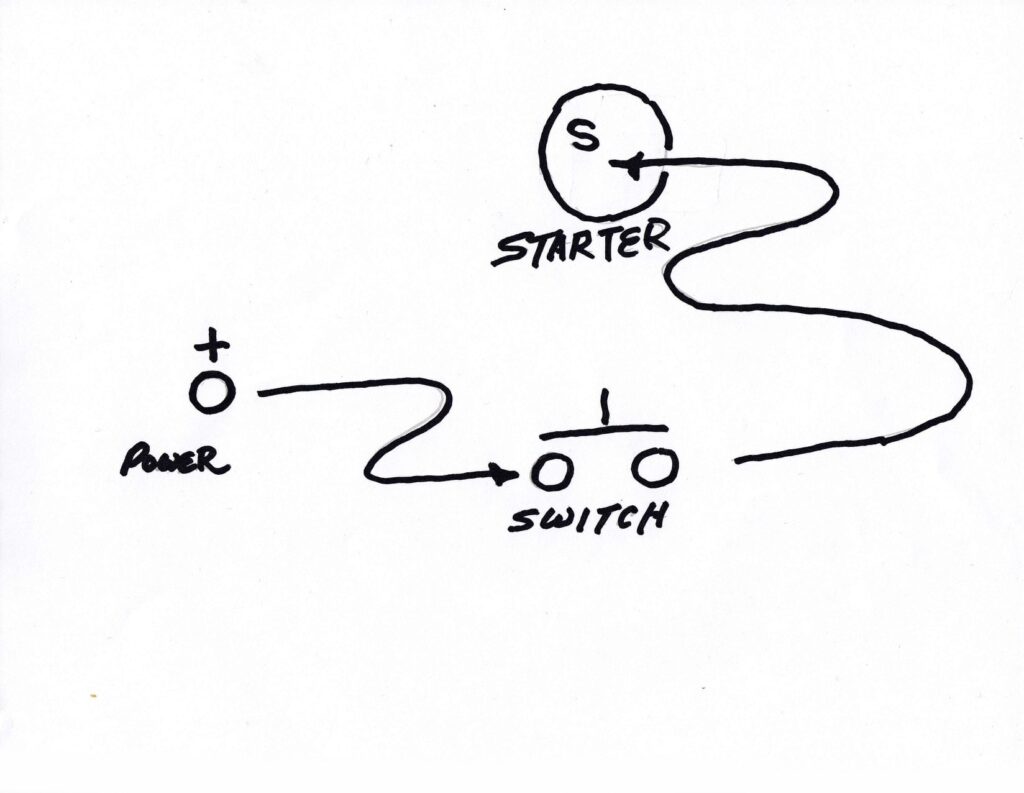

So far so good, but you can’t accomplish proper valve lash without tools. First and foremost, you’ll need something to turn the engine over. You can turn the engine over with a breaker bar (or in some cases, a ½-inch drive ratchet with a long handle). A crank damper bolt with a big head such as the ARP jobs shown in the accompanying photos makes it a wee bit easier. But a starter bump switch takes all of the hard work out of it. You just bump the engine over with the switch. Bump switches can be permanent (as shown in the accompanying photos) or you can buy a hand held remote switch from your local auto parts store. Switch wiring is basic too: One side of the switch goes to a 12 volt power source. The other goes to the “S” terminal on the starter. There’s a diagram in the accompanying photos.

The tools used on the Jesel rockers in the accompanying photos include a ½-inch box end wrench as well as a 5/32-inch Allen key. With other setups, and assuming the engine is equipped with roller rockers or poly locks of some sort, you’ll need a box end wrench along with an Allen-key to loosen, tighten and lock the adjuster. The dimensions of the box end wrench as well as the Allen-key depend upon the application.

There are several different tools dedicated to lash adjustment tools available today. The most common include an L-shaped box end wrench with a provision to insert a T-handle Allen key (shown in the accompanying photos). They work well and save some time when lashing valves because you don’t fumble with a pair of different wrenches. They’re available in a wide range of sizes (different size box ends and different size Allen-keys) to suit different poly lock arrangements.

Case-in-point are valve lash tools from LSM Racing. They offer several different examples with either a built-in ratchet handle or even a high end job with a built-in torque wrench (for shaft rocker systems). They come with three different T-handles (1/8, 5/32 and 3/16-inch) to cover a wide range of applications. The ratchet is pre-set to 22-foot-pounds and it can be modified up to 26-foot-pounds. It is not possible to use this tool on many stud mount rockers because it will not accept a larger (than 3/16-inch) T-handle hex key.

Something else to consider (and it’s actually very important) is a set of feeler gauges. The most common are either flat or with an offset blade. I personally prefer the flat versions when it comes to lashing valves. For me at least, the offset blades feel cumbersome when lashing valves. In any case, a good set of feeler gauges isn’t a costly proposition.

That’s not quite the end of it: One thing to always keep in mind is the actual feel and of the gauge as you’re setting valve lash. You really (Really) want to stay consistent. I tend to prefer a light drag on the feeler gauge while you’re moving it between the top of the valve and the roller tip.

In the end, you can pick and choose the lash system you prefer, but in our book, the “Exhaust Opening/Intake Closing” (“EO-IC”) method is simple and makes shop life far easier. Getting the right tools is important too. For a closer look at valve lash and the tools that go with it, check out the accompanying photos:

I’m always glad to see one of your articles in Racing Junk News. Always pick up some great insights. Thanks Wayne. The picture of the ARP damper nut on the short block shows a mechanical fuel pump on the engine. Do you use that setup in your Nova?

Hi John…Yes, I tried the Holley offshore marine pump (now obsolete) on the car. I used it with an Enderle by-pass valve and a composite (plastic) fuel pump pushrod on the roller cam. I struggled with getting the system stabilized. It would run great and then it wouldn’t (excess fuel pressure). I should have spent more time working out the shims and springs on the by-pass or I could have switched to a conventional fuel pressure regulator, but I was really concerned about the life expectancy of the composite pushrod. As a result, the car now has a Weldon electric pump and by-pass regulator. It runs great!