In our last issue, we discussed the loads placed upon a drag race universal joint. If you recall, even a lower horsepower Sportsman combination can place incredible amounts of torque on a universal joint. Factor in sticky tires and you just know the driveshaft is waiting to take the first exit.

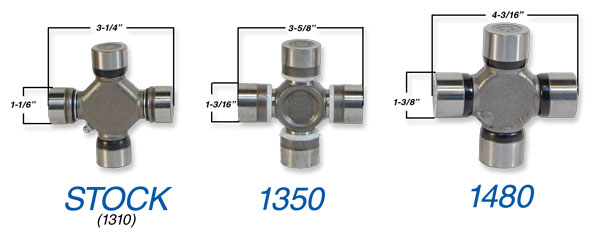

Fair enough, but how do you select a universal joint, and which size universal joint is best for the application? That depends, but according to Mark Williams, the workhorse in their race car driveshafts is the Spicer 1350 joint. In the accompanying photos, you’ll see why. It’s considerably larger than the joints commonly found under a production line car. Naturally, to use one of these joints, the shaft (along with the slip yoke and the rear pinion yoke) has to be changed, but that’s another story.

There’s more: At the rear flange, it’s common to use a u-bolt to hold the universal joint in place. But it too has its limits. Mark Williams has come up with a next generation u-bolt kit. The new second generation alloy steel u-bolt kit is a result of information gained from their driveshaft Torsion testing machine. Williams determined that the standard 3/8-inch 1350 u-bolt was prone to cycle failure when cycle testing at high torque levels. The one piece u-bolt allowed the joint to rock out of the differential companion flange.

The new design allows for a more secure attachment at the differential companion flange, significantly improving reliability. This cap setup can be retrofitted to any current style MW pinion yoke. A similar cap is available for MW 1480 series pinion yokes.

The solution was to surround the universal joint cups a full 360 degrees. This allowed the u-bolt to support up to 500 additional foot pounds of torque. Williams’ second gen u-bolt kits incorporate a bubble stud on the rear flange bolt hole, securely indexing the location. The straps are produced from a pre-heat treated Chromium-Molybdenum steel, while the studs are 150K material complete with rolled (not cut) threads. They’re sold as sets with accompanying 12 point reduced double hex nuts, and they fit all current Mark Williams forged billet rear pinion yokes.

So what’s the bottom line when it comes to u-joints? Get the driveshaft angles right, keep the pinion angle under control and don’t cheap out when it comes to universal joints. The reliability offered by following this advice can reap major rewards. Don’t get shafted, even if the parts you install are forever hidden from sight.

Leave a Reply