Gerator Oil Pumps

Click Here to Begin Slideshow

When it comes to oiling systems, the standard practice is to replace the oil pump with a high volume aftermarket job (or in the odd case, a high pressure, high volume job). When the majority of us add a new high volume pump, we just stick a fork into it and call it done. The oiling system is ready to roll. Or is it? Maybe not.

The reality is that most production car engines originally left the factory with a few things in mind: Build reasonable power, get good fuel ecomony, make it last for the duration of the warranty, and finally, build the thing as cheaply as possible. One place a bean counter can really cheap out is the oil pump. With a stock or even a modified factory style pump, you're forced to live with all of the factory pump shortcomings too: Cavitation, pump chatter, scattered spark, broken pickup tubes and so on. Yes, it’s true fixes exist for some of these issues, but there are definitely some better ideas out there.

One of those better ideas is the oil pump design from Titan Speed Engineering. They manufacture a series of very unique, dedicated race and high performance pumps with considerable improvements over OE-gear pumps. Titan’s Bob Sanders started with a clean sheet of paper and re-engineered the internal wet sump oil pump into a form more in line with the technology of a dry sump. No, it's not as cheap as a replacement spur gear pump, but neither are roller cams, stroker crankshafts or custom pistons. Bench testing has shown these sophisitcated oil pumps flow 30 to 50 percent more volume than all other conventional wet-sump examples. The pickup area is a whopping 80-90 percent larger too, but equally important, Titan's unique design is laid out to prevent the destructive cavitation that affects conventional "spur gear" oil pumps. More on cavitation later, but first let’s look at what it takes to actually move oil in an engine:

The Gerotor versus the Spur Gear

At first glance, the big gerotor pumps from Titan look quite a bit different from the spur gear pumps we’re used to seeing. Before digging into the differences, let's examine what goes on inside a conventional internal wet sump oiling system. Titan Speed Engineering’s Bob Sanders explains that when the time comes to pump oil in an engine, the first challenge is to get the oil into the pump. You have to keep in mind that the oil begins to get contaminated by unburned fuel and combustion byproducts as soon as the engine starts. All of these contaminants lower the lubricity of the oil, but more importantly, they make the oil much more difficult to pump. Basically, pumping the oil means squeezing the oil (along with the new contaminants) at between 60 and 150 pounds per square inch of pressure.

Sanders notes that as the fluid fills the pumping chambers in both spur gear and gerotor pumps, it must be at a lower pressure inside the chamber than outside of it:

“In order for the fluid to enter the pump, the more viscous the oil is (an extreme example is something like cold SAE 60 weight oil), then the harder it is to get the oil through the small holes in the oil pump suction screen. As the oil becomes warmer (and more contaminated), it tends to be less viscous and will enter the pump with less pressure drop. Unfortunately, there's a bit more going on; as the oil becomes hotter, the dissolved (or emulsified) fuel contamination becomes much closer to changing itself from a liquid state to a gaseous state (at this point, the fuel contaminants in the oil expand approximately 300 times). The pump is now pulling a vacuum reading on the oil, drawing it into the pump body. What the pump is pulling is a combination of oil and gaseous bubbles.

“This is where the two types of pumps (gerotor and spur gear) differ. The gerotor configuration has four lobes on the drive, which take a little over 180° of crankshaft rotation to fill the pumping chamber. Meanwhile, the spur gear design (using a 12 tooth gear configuration as an example) has only 60° of crankshaft rotation to accomplish the same thing. Since the gerotor has more than three times the work time to fill its chamber, it allows the oil to accelerate smoothly into the pump chamber, then shut off slowly as it completes its cycle. This smooth action is less likely to pull gas out of the entering fluid than a spur gear pump, which is trying to fill the chamber three times faster. This is like shaking a soda can before you open it. At 9,000 RPM, the spur gear pump is trying to fill itself 54,000 times per minute. Meanwhile, the gerotor is trying to fill itself at 18,000 times per minute.”

The Definition Of Pump Cavitation

Oil pump cavitation isn't good. That’s a well known fact. But what really happens when a pump cavitates? Sanders provides this explanation:

"Cavitation is always destructive - especially to objects that are near to it. Cavitation is what occurs when a gas is forced back into a liquid state. Basically, it's imploding bubbles. This causes the horsepower required to drive a pump to increase by three to five times. Meanwhile, the oil coming out of the discharge of a pump drops to between 10-20 percent in volume. The total volume of the oil and the gas bubbles combined is often higher, which can make pressure measurements fool you.

"To compare how the two pumps discharge oil, you can see how the gerotor inherently is much less likely to cavitate. Again, the spur gear takes the same 60° of crank rotation to hammer the oil (and bubbles) up to the selected bypass pressure. The gerotor design discharges three times slower and smoother, through the 180° crank rotation. Significantly fewer bubbles implode if you squeeze them slower."

There is only one advantage to a very large pump that doesn't cavitate upon acceleration, but it's a big one: This type of pump oils the bearings before the load is on them instead of after. Basically, both a spur gear and gerotor pump put the same amount of oil into the lube system at a given pressure if there is no cavitation. Either configuration will only pump oil if there is oil in the pan.

Progressive Pulse Technology

By design, the bypass in a spur gear must be discharged back to the pan. This translates into lost energy. Sanders explains that if the bypass in a spur gear pump was internal, this pump configuration would cavitate itself into destruction. On the other hand, the bypass system in a gerotor can be configured to pump into the upper field (suction stage) kidney. According to Sanders, this basically supercharges one end of the suction stage, which reduces the load on the pump drive - especially at high RPM. In tuning the shape and volume of the suction and discharge kidneys Titan sets them up to so that they are technically "On The Cam" at 4000 to 12,000 RPM's. Titan Speed Engineerings calls it “Progressive Pulse Technology.”

The housings used on Titan Pro Series pumps are CNC-machined from aircraft-quality 7075 T651 aluminum, then hard-anodized. Meanwhile, housings used on Sportsman Series pumps are manufactured from cast 356 alloy and heat-treated to a T6 specification. Shafts are heat-treated 300M tool steel. Special features include an internal pressure-relief section. Titan bench tests each before shipping. All of their pumps are infinitely adjustable and fully rebuildable (even the press-in bearing is easily replaceable -- worn housings can simply be bored and fitted with new liners). Basically, it’s a long life configuration – something the OEM’s never took into consideration when it came to oil pump design.

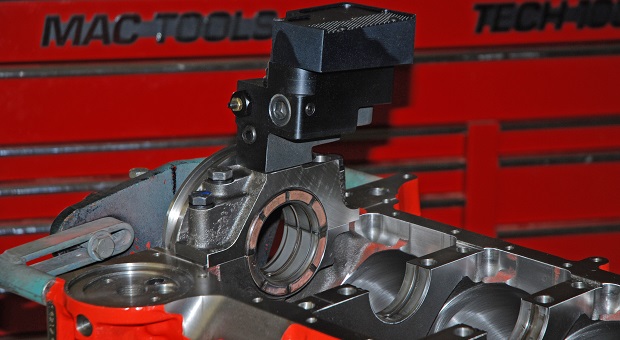

Peruse the accompanying photos closely. You will discover just how compact this pump design really is, and you'll be able see how it differs from a common spur gear pump. The bottom line here is, a really good oil pump can certainly spell the difference between long and short term engine longevity. That's something that should be important for every racer.

When it comes to oiling systems, the standard practice is to replace the oil pump with a high volume aftermarket job (or in the odd case, a high pressure, high volume job). When the majority of us add a new high volume pump, we just stick a fork into it and call it done. The oiling system is ready to roll. Or is it? Maybe not.

The reality is that most production car engines originally left the factory with a few things in mind: Build reasonable power, get good fuel ecomony, make it last for the duration of the warranty, and finally, build the thing as cheaply as possible. One place a bean counter can really cheap out is the oil pump. With a stock or even a modified factory style pump, you're forced to live with all of the factory pump shortcomings too: Cavitation, pump chatter, scattered spark, broken pickup tubes and so on. Yes, it’s true fixes exist for some of these issues, but there are definitely some better ideas out there.

One of those better ideas is the oil pump design from Titan Speed Engineering. They manufacture a series of very unique, dedicated race and high performance pumps with considerable improvements over OE-gear pumps. Titan’s Bob Sanders started with a clean sheet of paper and re-engineered the internal wet sump oil pump into a form more in line with the technology of a dry sump. No, it's not as cheap as a replacement spur gear pump, but neither are roller cams, stroker crankshafts or custom pistons. Bench testing has shown these sophisitcated oil pumps flow 30 to 50 percent more volume than all other conventional wet-sump examples. The pickup area is a whopping 80-90 percent larger too, but equally important, Titan's unique design is laid out to prevent the destructive cavitation that affects conventional "spur gear" oil pumps. More on cavitation later, but first let’s look at what it takes to actually move oil in an engine:

The Gerotor versus the Spur Gear

At first glance, the big gerotor pumps from Titan look quite a bit different from the spur gear pumps we’re used to seeing. Before digging into the differences, let's examine what goes on inside a conventional internal wet sump oiling system. Titan Speed Engineering’s Bob Sanders explains that when the time comes to pump oil in an engine, the first challenge is to get the oil into the pump. You have to keep in mind that the oil begins to get contaminated by unburned fuel and combustion byproducts as soon as the engine starts. All of these contaminants lower the lubricity of the oil, but more importantly, they make the oil much more difficult to pump. Basically, pumping the oil means squeezing the oil (along with the new contaminants) at between 60 and 150 pounds per square inch of pressure.

Sanders notes that as the fluid fills the pumping chambers in both spur gear and gerotor pumps, it must be at a lower pressure inside the chamber than outside of it:

“In order for the fluid to enter the pump, the more viscous the oil is (an extreme example is something like cold SAE 60 weight oil), then the harder it is to get the oil through the small holes in the oil pump suction screen. As the oil becomes warmer (and more contaminated), it tends to be less viscous and will enter the pump with less pressure drop. Unfortunately, there's a bit more going on; as the oil becomes hotter, the dissolved (or emulsified) fuel contamination becomes much closer to changing itself from a liquid state to a gaseous state (at this point, the fuel contaminants in the oil expand approximately 300 times). The pump is now pulling a vacuum reading on the oil, drawing it into the pump body. What the pump is pulling is a combination of oil and gaseous bubbles.

“This is where the two types of pumps (gerotor and spur gear) differ. The gerotor configuration has four lobes on the drive, which take a little over 180° of crankshaft rotation to fill the pumping chamber. Meanwhile, the spur gear design (using a 12 tooth gear configuration as an example) has only 60° of crankshaft rotation to accomplish the same thing. Since the gerotor has more than three times the work time to fill its chamber, it allows the oil to accelerate smoothly into the pump chamber, then shut off slowly as it completes its cycle. This smooth action is less likely to pull gas out of the entering fluid than a spur gear pump, which is trying to fill the chamber three times faster. This is like shaking a soda can before you open it. At 9,000 RPM, the spur gear pump is trying to fill itself 54,000 times per minute. Meanwhile, the gerotor is trying to fill itself at 18,000 times per minute.”

The Definition Of Pump Cavitation

Oil pump cavitation isn't good. That’s a well known fact. But what really happens when a pump cavitates? Sanders provides this explanation:

"Cavitation is always destructive - especially to objects that are near to it. Cavitation is what occurs when a gas is forced back into a liquid state. Basically, it's imploding bubbles. This causes the horsepower required to drive a pump to increase by three to five times. Meanwhile, the oil coming out of the discharge of a pump drops to between 10-20 percent in volume. The total volume of the oil and the gas bubbles combined is often higher, which can make pressure measurements fool you.

"To compare how the two pumps discharge oil, you can see how the gerotor inherently is much less likely to cavitate. Again, the spur gear takes the same 60° of crank rotation to hammer the oil (and bubbles) up to the selected bypass pressure. The gerotor design discharges three times slower and smoother, through the 180° crank rotation. Significantly fewer bubbles implode if you squeeze them slower."

There is only one advantage to a very large pump that doesn't cavitate upon acceleration, but it's a big one: This type of pump oils the bearings before the load is on them instead of after. Basically, both a spur gear and gerotor pump put the same amount of oil into the lube system at a given pressure if there is no cavitation. Either configuration will only pump oil if there is oil in the pan.

Progressive Pulse Technology

By design, the bypass in a spur gear must be discharged back to the pan. This translates into lost energy. Sanders explains that if the bypass in a spur gear pump was internal, this pump configuration would cavitate itself into destruction. On the other hand, the bypass system in a gerotor can be configured to pump into the upper field (suction stage) kidney. According to Sanders, this basically supercharges one end of the suction stage, which reduces the load on the pump drive - especially at high RPM. In tuning the shape and volume of the suction and discharge kidneys Titan sets them up to so that they are technically "On The Cam" at 4000 to 12,000 RPM's. Titan Speed Engineerings calls it “Progressive Pulse Technology.”

The housings used on Titan Pro Series pumps are CNC-machined from aircraft-quality 7075 T651 aluminum, then hard-anodized. Meanwhile, housings used on Sportsman Series pumps are manufactured from cast 356 alloy and heat-treated to a T6 specification. Shafts are heat-treated 300M tool steel. Special features include an internal pressure-relief section. Titan bench tests each before shipping. All of their pumps are infinitely adjustable and fully rebuildable (even the press-in bearing is easily replaceable -- worn housings can simply be bored and fitted with new liners). Basically, it’s a long life configuration – something the OEM’s never took into consideration when it came to oil pump design.

Peruse the accompanying photos closely. You will discover just how compact this pump design really is, and you'll be able see how it differs from a common spur gear pump. The bottom line here is, a really good oil pump can certainly spell the difference between long and short term engine longevity. That's something that should be important for every racer.

![[Gallery] Show us Your Mustang! Celebrating 60 Years of Mustang](https://www.racingjunk.com/news/wp-content/uploads/2024/04/Al-Liebmann-376x206.webp)

![[Gallery] Okolona Street Rods Kentuckiana V Foundation Car Show](https://www.racingjunk.com/news/wp-content/uploads/2022/04/IMG_0774-e1650040587750-376x206.jpg)

![[Gallery] Road Rats Car Show](https://www.racingjunk.com/news/wp-content/uploads/2022/05/2A-e1651770667920-376x206.jpg)

Where are the PHOTOS?

Pictures don’t work…

up top