In an earlier segment of The Burnout, we initiated our look at drag race brakes. We examined the different types of rotors out there, along with the various materials used and why each type is used where. Fair enough. But you cannot mount a rotor to a hub or drive it by an axle flange without some form of hat.

Brake Hats

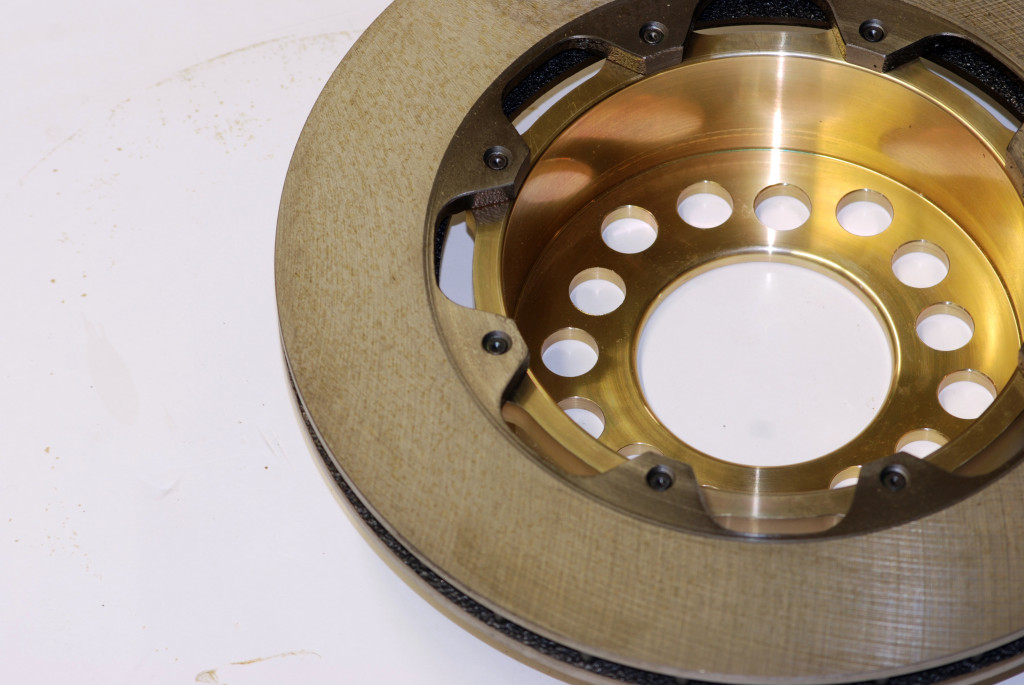

In an OEM production line car, the brake rotor and “hat” are commonly one piece assemblies. They’re cheap and easy to manufacture. A one-piece steel rotor has a large amount of mass on one side. Because of this, a one-piece rotor also has a natural tendency to warp slightly. In turn, the pads wear on an angle, which effectively reduces contact area and can cause all sorts of brake problems. That’s why, in most high-end high performance and race car applications, the hat is almost always made as a separate component. The rotor is attached to the hat that is attached to either the wheel hub or the axle-housing end or flange. There’s more to a hat than simply providing a place to mount the rotor. By design, the hat provides a long path for heat to travel from the brake swept area surface to the wheel bearing. If this pathway is short, then wheel bearings will die a very quick death.

Although hats can be produced from different materials, the most common in motorsports is aluminum alloy. It’s perfect for the application since it’s very light, and dissipates heat very quickly. Plus, aluminum both reduces the weight, and reduces the thermal stress upon the rotor. Since aluminum expands at a rate greater than iron or steel, it tends to equalize the expansion difference created by the sometimes-extreme temperature of the rotor. Quality engineered hats will take the “heat path” into consideration during design. This allows the heat to be directed away from the bearings, permitting the wheel (which acts as a huge heat sink) to absorb the temperature.

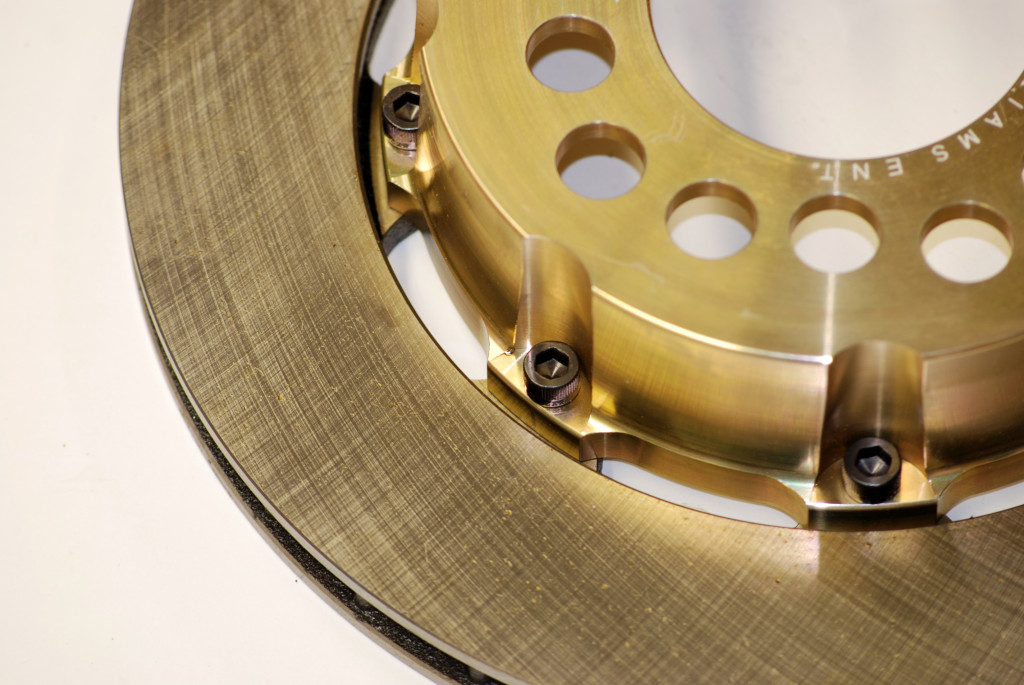

Two different types of hat-to-rotor mounting designs are commonly used: Bolts and drive lugs. As mentioned in the earlier segment manufacturers such as Mark Williams use a drive lug system for Carbon/Carbon rotors and the Slot-Drive (TM) system if steel discs. These drive lugs are actually a series of radial slots built into the rotor that act with drive lugs in (or attached to) the hat. These pieces act as a spline to transmit the brake torque back to the hat. When cap screws (bolts) are used to affix solid steel rotors expansion and contraction is a issue. If cap screws are used, then the hat must be designed to be relatively thin and flexible. It must also be designed to work without breaking. The reason for this is of course, expansion. The hat must expand with the rotor as it builds heat but a solid mounted steel disc will keep shrinking smaller as it cools. The result is cupped rotors and the fasteners have so much pressure from the shrinkage you can not remove the fasteners without twisting them off.

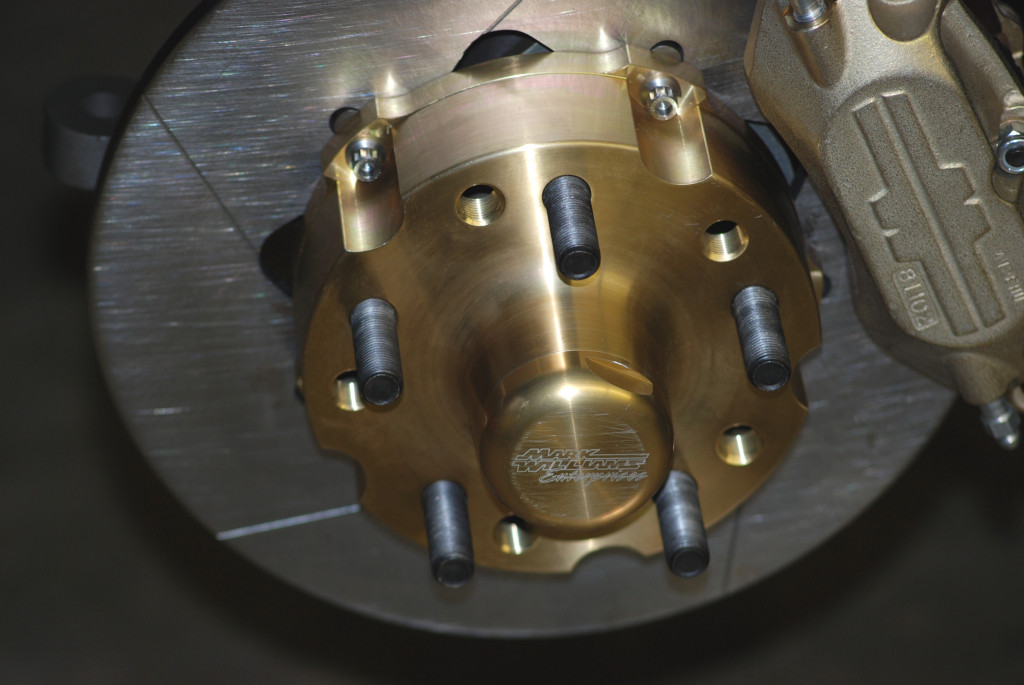

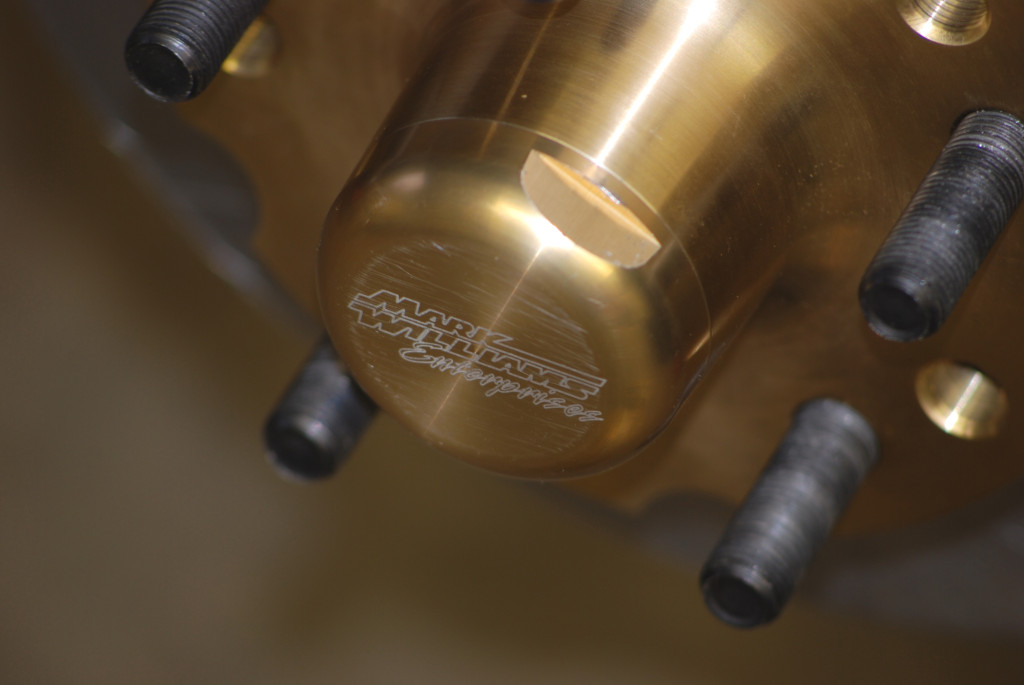

Brake Hubs

High quality drag race front brake hubs should be designed using aircraft grade aluminum. Typically, a quality setup will include a single piece hub and brake hat configuration. Mark Williams notes that by manufacturing a relatively large diameter hub, the rotor size can effectively be reduced. In turn, this reduces the rotating mass (obviously, since the weight of the rotor is less). Most manufacturers offer hubs drilled with both 4-1/2-inch and 4-3/4-inch bolt patterns (the most common in drag racing). When it comes to wheel studs for the nose of your car, don’t bother with 7/16-inch diameter jobs. Instead, use ½-inch studs and corresponding lug nuts (no matter what the bolt circle).

Other important issues when it comes to brake hubs is the bearing and seal type. Truthfully, there are any number of bearings and seals manufactured in China, India and other “far away lands” today. And personally, I don’t think you can trust any of them. You can still buy good quality bearings and seals manufactured in North America or Europe (Timken is a good example). Quality brake kits will include these pieces.

As a side note, when installing a new brake setup, use quality synthetic wheel bearing grease. We’ve had a few local shops tell us they’ve never heard of synthetic bearing grease, but trust us, it’s out there and in a racing application, much better suited (especially from a heat perspective) than standard stuff.

Something else you have to consider when buying a brake kit is the spindle. Many brake kits for various cars mandate spindle modifications. For example, the 1987 (and up) Mustang spindles shown here had the OEM brake caliper mounts milled off. The manufacturer can handle that for you or alternatively, they can supply drawings and dimensions to show where you can trim off the mount ears. When the ears are milled off, the manufacturer provides a custom bracket to mount their own caliper. Just be certain the caliper mount bracket is robust. Here’s why: Many years ago, this writer was involved with a Super Stock drag race Firebird. It was a fresh car with new brakes sourced from a “reputable” manufacturer. While in the burnout box, the one front caliper mount actually fractured before a pass. Fortunately, the failure occurred here. If it had taken place at the big end of the track, the results would have been catastrophic. That reputable manufacturer is no longer in business. But it’s food for thought.

Stay tuned to the pages of The Burnout: Next up, we’ll take a look at business end of the system – the brake caliper.

Previous parts: Part 1

###

Source: Brake Dance – 2

Mark Williams Enterprises

Website: www.markwilliams.com

—————————————————————————————————————————————

About the author: Wayne Scraba is a racecar junky. His background includes operation of his own speed shop, building racecars (some you might be familiar with, but we won’t get into it here), building hot rod street machines; he’s built custom motorcycles, restored muscle cars and played with off road bikes. Scraba has a sundry background in writing too: He’s toiled as a magazine Editor, a technical Editor, a free-lance magazine contributor and authored five automotive books. His byline (well over 4,500 articles worth) has appeared in well over sixty different high performance automotive, motorcycle and aviation magazines worldwide. Racecar junky? Most likely!

—————————————————————————————————————————————

Leave a Reply