Lines, Clamps and Fasteners for Your Race Car

Click Here to Begin Slideshow

Tubing, hoses and wire bundles are pretty much the norm in any car – race or street. Sure, in some relatively simple race cars there aren’t as many hoses or wires as you’ll find in a modern passenger car, but the still exist. How you fasten those bits is important too. Fasteners are everywhere in a motor vehicle, and in a race car, they’re particularly important - although in any number of cars, it’s clear some folks don’t give it much thought. We’ve all looked at cars with zip-tied hoses and wire looms running helter-skelter. Some old-timers laugh when they see it, too: “Zip ties are just a modern day counterpart to baling wire.” Naturally, when putting a car together, the idea of cleanly fastening hoses or wire looms usually isn’t one of those things that make your heart pound. And it’s sure not on par with firing an engine up for the first time. But on the other hand, having a wire harness go up in smoke because it rubbed against a moving part isn’t exactly fun either. So what’s the answer?

Turn back the clock over 70 years and look at “aircraft” clamps (also known as “cushioned clamps”). What the heck is an aircraft or cushioned clamp? It's a clamp that is used to support metal tubing, hose or electrical harnesses. The cushion provides protection to the item being supported by firmly holding the item and preventing, or "cushioning," the effects of vibration and abrasion. And it’s one of the (few) accepted methods of securing stuff like hoses, tubing and wire harnesses in an aviation application.

You might recognize the phrase "Adel" clamps. The "Adel" clamp is also referred to as a MS21919 aircraft clamp (“MS” equals Military Spec). Here’s the deal (and you can see that cushioned clamps fit in perfectly with period hot rods): The Adel Fastener Company was established in 1938 in Burbank, California. Over the years, Adel has become an established industry leader in aerospace clamp and elastomer development. To be quite honest, Adel likely manufactured a large portion of the MS21919 clamps in existence; however, there have been other companies, which, over the years, have manufactured them. Nonetheless, the term "Adel clamp" stuck, and it's used interchangeably with all similar varieties of cushion clamps, even if they aren't manufactured by Adel Fasteners.

Technically speaking, the MS21919 clamp is properly called a loop clamp. There are other varieties, but this versatile clamp is the most common in aerospace applications. Common sizes typically range from 1/16-inch to 4 inches in size. When you look at a typical cushion clamp part number, you'll often find a series of suffixes that follow the Mil Spec number. Typically, the first will be a "W," which stands for "Wedge.” The idea here is that the design of the cushion prevents something like a small wire in a bundle from being squeezed out during the clamping process. Clamps with sizes below 50 are designed with the wedge feature (more on sizing later).

The characters that follow the "W" are also important. Below is a breakdown of clamp suffix codes (these are the two characters that follow the "W"):

• CE Corrosion Resistant Steel Band, Ethylene Propylene Cushion (275° F)

• CF Corrosion Resistant Steel Band, Nitrile Propylene Cushion (200° F)

• CG Corrosion Resistant Steel Band, Chloroprene Cushion (212° F)

• CH Corrosion Resistant Steel Band, Silicone Cushion (400° F)

• CJ Corrosion Resistant Steel Band, Fluorosilicone Cushion (450° F)

• DE Aluminum Band, Ethylene Propylene Cushion (212° F)

• DF Aluminum Band, Nitrile Cushion (212° F)

• DG Aluminum Band, Chloroprene Cushion (212° F)

• F Low Carbon Steel Band, Nitrile Cushion (212° F)

• G Low Carbon Steel Band, Chloroprene Cushion (212° F)

• H Low Carbon Steel Band, Silicon Cushion (400° F)

So far so good. The clamps are available in several different base materials as well as several different cushion materials. The most popular materials for the clamp are aluminum and stainless steel (300 series stainless steel as well as 17-7PH). Cushion clamps are also available manufactured with exotic metals such as Inconel and other exotic materials we likely don’t need to consider. Cushion designs include "flat with wedge,” as described above, along with a "saw tooth" configuration, an "electrical" style and others. The most common cushion you'll find is the wedge design. The environment in which the clamp will be used determines the type of cushion material. When searching for clamps, you'll often find that clamps with an "F," "G" or "H" suffix (those with low carbon steel bands) are difficult to locate. Why? Simple. They are not recommended for use on a new aircraft design, and because of that have been discontinued for almost twenty years.

The clamp strap and cushion material determines the temperature range for which the clamp is designed. Temperatures from -65 to +450 degrees Fahrenheit can be endured depending primarily on cushion material selection. Check the above chart to see which clamps (and materials) live under specific temperature ranges.

There’s more, too: In order to recognize the clamps, a series of color codes is incorporated. The following is an alphabetical breakdown of the specific cushion color codes along with pertinent cushion information:

• Black (sometimes with blue identity patch): The clamp is manufactured with a Chloroprene cushion. This is a general-purpose clamp that can be used in areas that may be contaminated with petroleum-based hydraulic fluids as well as fuel spills. The material has excellent ozone resistant characteristics, but is not resistant to phosphate-ester based fluids. Do not use on titanium tubing.

• Blue: Fluorosilicone is the material used for the cushion in this clamp. It is ideal for use in an elevated temperature application where petroleum based fluid contamination may be a factor. The material is unaffected by ozone; however, it is not resistant to phosphate-ester based fluids.

• Purple: The clamp cushion material is Ethylene Propylene. It is designed for use where contamination by phosphate-ester hydraulic fluid and other synthetic fluids is possible. The material has excellent ozone resistance, but it is not resistant to petroleum-based fluids.

• Red: This is a Silicone-based clamp cushion, and was only used on clamps manufactured from low carbon steel. It is now obsolete.

• White (natural): Silicone is used as the cushion material. It is engineered for use in elevated temperature applications where phosphate-ester based fluid and other synthetic fluid may present contamination. This cushion material is not resistant to petroleum based fluids, but it is unaffected by ozone.

• Yellow (solid): The cushion material is Nitrile. It is primarily used in applications where it is immersed in fuel or comes in contact with fuel vapors. It has good ozone resistance characteristics, but it is not resistant to phosphate-ester based fluids. In addition, it should not be used on titanium tubing.

###

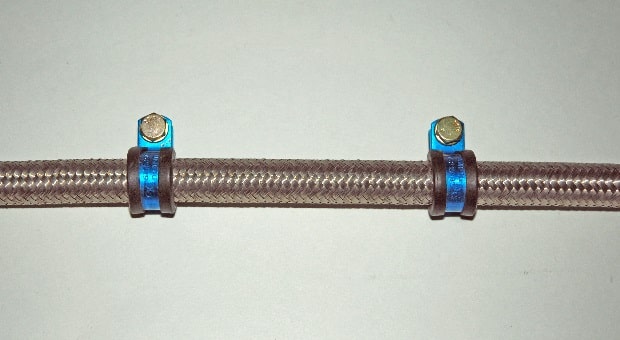

The final groups of characters you will find on an “Adel” clamp are numbers that describe the internal diameter of a closed clamp in increments of 1/16-inch. As an example, clamp number MS21219WDG10 (as shown in the accompanying photos) incorporates an aluminum strap inside a black chloroprene cushion and is sized to support a 10/16 or 5/8-inch diameter piece of tube or a wire bundle. Operating temperature is not to exceed 212 degrees F.

If you haven't gathered by now, your choices when clamping something in your race car are pretty good. And if you have a plumbing or wiring fastening nightmare on your hands, take a closer look at these clamps. They’re relatively inexpensive and they do their job. It’s an easier way to “walk the line.”

Tubing, hoses and wire bundles are pretty much the norm in any car – race or street. Sure, in some relatively simple race cars there aren’t as many hoses or wires as you’ll find in a modern passenger car, but the still exist. How you fasten those bits is important too. Fasteners are everywhere in a motor vehicle, and in a race car, they’re particularly important - although in any number of cars, it’s clear some folks don’t give it much thought. We’ve all looked at cars with zip-tied hoses and wire looms running helter-skelter. Some old-timers laugh when they see it, too: “Zip ties are just a modern day counterpart to baling wire.” Naturally, when putting a car together, the idea of cleanly fastening hoses or wire looms usually isn’t one of those things that make your heart pound. And it’s sure not on par with firing an engine up for the first time. But on the other hand, having a wire harness go up in smoke because it rubbed against a moving part isn’t exactly fun either. So what’s the answer?

Turn back the clock over 70 years and look at “aircraft” clamps (also known as “cushioned clamps”). What the heck is an aircraft or cushioned clamp? It's a clamp that is used to support metal tubing, hose or electrical harnesses. The cushion provides protection to the item being supported by firmly holding the item and preventing, or "cushioning," the effects of vibration and abrasion. And it’s one of the (few) accepted methods of securing stuff like hoses, tubing and wire harnesses in an aviation application.

You might recognize the phrase "Adel" clamps. The "Adel" clamp is also referred to as a MS21919 aircraft clamp (“MS” equals Military Spec). Here’s the deal (and you can see that cushioned clamps fit in perfectly with period hot rods): The Adel Fastener Company was established in 1938 in Burbank, California. Over the years, Adel has become an established industry leader in aerospace clamp and elastomer development. To be quite honest, Adel likely manufactured a large portion of the MS21919 clamps in existence; however, there have been other companies, which, over the years, have manufactured them. Nonetheless, the term "Adel clamp" stuck, and it's used interchangeably with all similar varieties of cushion clamps, even if they aren't manufactured by Adel Fasteners.

Technically speaking, the MS21919 clamp is properly called a loop clamp. There are other varieties, but this versatile clamp is the most common in aerospace applications. Common sizes typically range from 1/16-inch to 4 inches in size. When you look at a typical cushion clamp part number, you'll often find a series of suffixes that follow the Mil Spec number. Typically, the first will be a "W," which stands for "Wedge.” The idea here is that the design of the cushion prevents something like a small wire in a bundle from being squeezed out during the clamping process. Clamps with sizes below 50 are designed with the wedge feature (more on sizing later).

The characters that follow the "W" are also important. Below is a breakdown of clamp suffix codes (these are the two characters that follow the "W"):

• CE Corrosion Resistant Steel Band, Ethylene Propylene Cushion (275° F)

• CF Corrosion Resistant Steel Band, Nitrile Propylene Cushion (200° F)

• CG Corrosion Resistant Steel Band, Chloroprene Cushion (212° F)

• CH Corrosion Resistant Steel Band, Silicone Cushion (400° F)

• CJ Corrosion Resistant Steel Band, Fluorosilicone Cushion (450° F)

• DE Aluminum Band, Ethylene Propylene Cushion (212° F)

• DF Aluminum Band, Nitrile Cushion (212° F)

• DG Aluminum Band, Chloroprene Cushion (212° F)

• F Low Carbon Steel Band, Nitrile Cushion (212° F)

• G Low Carbon Steel Band, Chloroprene Cushion (212° F)

• H Low Carbon Steel Band, Silicon Cushion (400° F)

So far so good. The clamps are available in several different base materials as well as several different cushion materials. The most popular materials for the clamp are aluminum and stainless steel (300 series stainless steel as well as 17-7PH). Cushion clamps are also available manufactured with exotic metals such as Inconel and other exotic materials we likely don’t need to consider. Cushion designs include "flat with wedge,” as described above, along with a "saw tooth" configuration, an "electrical" style and others. The most common cushion you'll find is the wedge design. The environment in which the clamp will be used determines the type of cushion material. When searching for clamps, you'll often find that clamps with an "F," "G" or "H" suffix (those with low carbon steel bands) are difficult to locate. Why? Simple. They are not recommended for use on a new aircraft design, and because of that have been discontinued for almost twenty years.

The clamp strap and cushion material determines the temperature range for which the clamp is designed. Temperatures from -65 to +450 degrees Fahrenheit can be endured depending primarily on cushion material selection. Check the above chart to see which clamps (and materials) live under specific temperature ranges.

There’s more, too: In order to recognize the clamps, a series of color codes is incorporated. The following is an alphabetical breakdown of the specific cushion color codes along with pertinent cushion information:

• Black (sometimes with blue identity patch): The clamp is manufactured with a Chloroprene cushion. This is a general-purpose clamp that can be used in areas that may be contaminated with petroleum-based hydraulic fluids as well as fuel spills. The material has excellent ozone resistant characteristics, but is not resistant to phosphate-ester based fluids. Do not use on titanium tubing.

• Blue: Fluorosilicone is the material used for the cushion in this clamp. It is ideal for use in an elevated temperature application where petroleum based fluid contamination may be a factor. The material is unaffected by ozone; however, it is not resistant to phosphate-ester based fluids.

• Purple: The clamp cushion material is Ethylene Propylene. It is designed for use where contamination by phosphate-ester hydraulic fluid and other synthetic fluids is possible. The material has excellent ozone resistance, but it is not resistant to petroleum-based fluids.

• Red: This is a Silicone-based clamp cushion, and was only used on clamps manufactured from low carbon steel. It is now obsolete.

• White (natural): Silicone is used as the cushion material. It is engineered for use in elevated temperature applications where phosphate-ester based fluid and other synthetic fluid may present contamination. This cushion material is not resistant to petroleum based fluids, but it is unaffected by ozone.

• Yellow (solid): The cushion material is Nitrile. It is primarily used in applications where it is immersed in fuel or comes in contact with fuel vapors. It has good ozone resistance characteristics, but it is not resistant to phosphate-ester based fluids. In addition, it should not be used on titanium tubing.

###

The final groups of characters you will find on an “Adel” clamp are numbers that describe the internal diameter of a closed clamp in increments of 1/16-inch. As an example, clamp number MS21219WDG10 (as shown in the accompanying photos) incorporates an aluminum strap inside a black chloroprene cushion and is sized to support a 10/16 or 5/8-inch diameter piece of tube or a wire bundle. Operating temperature is not to exceed 212 degrees F.

If you haven't gathered by now, your choices when clamping something in your race car are pretty good. And if you have a plumbing or wiring fastening nightmare on your hands, take a closer look at these clamps. They’re relatively inexpensive and they do their job. It’s an easier way to “walk the line.”

![[Gallery] Show us Your Mustang! Celebrating 60 Years of Mustang](https://www.racingjunk.com/news/wp-content/uploads/2024/04/Al-Liebmann-376x206.webp)

![[Gallery] Okolona Street Rods Kentuckiana V Foundation Car Show](https://www.racingjunk.com/news/wp-content/uploads/2022/04/IMG_0774-e1650040587750-376x206.jpg)

![[Gallery] Road Rats Car Show](https://www.racingjunk.com/news/wp-content/uploads/2022/05/2A-e1651770667920-376x206.jpg)

Leave a Reply