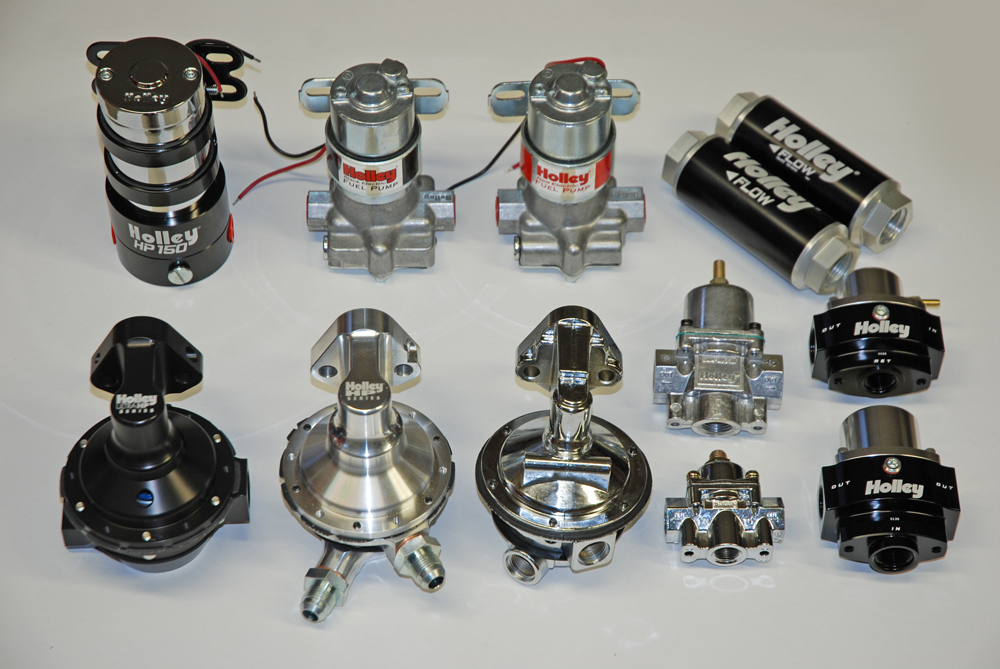

Previously, we looked at fuel pumps – electric models in part one and mechanical jobs in part two of the Fueling The Flame Drag Racing 101 series. Several of those pumps mandate an external fuel pressure regulator. Like fuel pumps, there are also a number of different styles of regulators available, some specifically for carbureted applications and others for EFI.

Before the fuel enters the fuel line or fuel rail(s) found on the engine, and ultimately, before it reaches the fuel bowls or the fuel injectors, some sort of device is (often) necessary to harness the flow and pressure of the fuel. That job belongs to a fuel pressure regulator. For EFI applications, a regulator is mandatory. For carbureted applications with fuel pump pressures higher than approximately 7.5 PSI, then a regulator is required too. For these carbureted applications, too much fuel pressure for a given needle and seat assembly can overload the needle and seat and may cause flooding or drivability problems. In the case of our Holley examples (below), each fuel pressure regulator is fully adjustable so regulating the fuel pressure to your engines needs is a simple task. Typically these regulators are pre-set at the factory so there is no guesswork when first installing the regulator.

On the EFI front, there are some companies that build fixed regulators (most common in OEM applications), but others (particularly aftermarket vendors) offer adjustable regulators. What’s the advantage? Simple. An adjustable regulator allows an engine tuner to test varying levels of fuel pressure in order to find the exact level the engine is most “happy” with. Typically, you’ll want a regulator that doesn’t “creep”. Creeping means the regulator has difficulty maintaining a set level of pressure. Most high quality (more costly) regulators meet these criteria.

Some high flow EFI systems also by-pass the fuel. What that means is they take in more fuel than is necessary and return the balance to the reservoir (gas tank). This is done to eliminate fuel aeration – the idea here is to efficiently pump fuel, not a frothy mix of air and fuel. When equipped with a by-pass system, a valve of sorts controls the amount of fuel that actually bypasses and is returned to the fuel tank.

As you can see, regulators are rather important. In many cases, the car couldn’t operate without one. For a closer look, at some different regulator options, check out the following:

Holley #12-803

This is pretty much the standard fuel pressure regulator that has been used for what seems like forever. At one time, they were painted blue (and that was the identifier for most speed shops). Today, they’re shiny with a tumbled exterior. This regular has a 0.220-inch restriction and has 3/8-inch NPT ports – one inlet and two outlets (non-return style). The range of adjustment is between 4-1/2 PSI to 9 PSI.

Holley #12-704

Holley’s 12-704 fuel pressure regulator looks a lot like the standard 12-803 model until you place them side-by-side. The 12-704 is much larger. Case-in-point are the inlet and dual outlet ports. For this regulator, they large ½-inch NPT sizes. This regulator also has a much larger restriction size (0.437-inch). It is not a by-pass (return style) regulator, however it’s suitable for use with gasoline or alcohol fuels. The range of adjustment is from 4.5-PSI to 9-PSI.

Holley #12-843

Next up is a huge by large billet aluminum regulator. This is a non-return regulator with a range of 4.5-9-PSI. It’s obviously for carbureted applications. The big billet regulator features a huge -10 AN inlet port along with a pair of -8 AN outlet ports. Both of these ports mandate an O-ring for sealing. Bottom line here is, this is a big, high volume regulator that can be used with electric or mechanical fuel pumps.

Holley 12-848

The last regulator in our selection is a billet bypass job that is designed for use in electronic fuel injection applications. The billet aluminum regulator has a range of 40-70 PSI and is equipped with a -10 AN O-ring inlet; a -10 AN O-ring outlet and a -8 AN O-ring return port (that should be plumbed back to the fuel tank). There’s a vacuum reference port near the top of the regulator. This port can be connected to full manifold vacuum to slightly decrease fuel pressure at idle and cruise. Holley notes this is a requirement on forced induction engines, so that the differential fuel pressure stays constant under boost.

Next issue, we’ll take a closer look at fuel filters along with a brief look at some mounting and plumbing ideas. Meanwhile, check out the accompanying photos of the four regulators we discussed in the article:

Source – Fueling The Flame – 3

Holley Performance Products

1801 Russellville Rd

Bowling Green, KY 42101

PH: 270-782-2900

http://www.holley.com

Leave a Reply