My buddy Craig Poust, owner of Justin Sane Racing Products, is known for doing insane things to engines. For instance, other than one (which I will write about shortly), all of his previous projects have involved junkyard LS engines, most of which have well over 100k miles on the odometer. What’s insane about that? He doesn’t rebuild them. He usually reuses the old gaskets, too. Additionally, when he’s finished playing with the engines, they produce anywhere from 800 to more than 1300 HP. I’ll walk you through one of Craig’s latest projects in this article.

Introducing the Justin Sane Racing Products Parts Truck Build

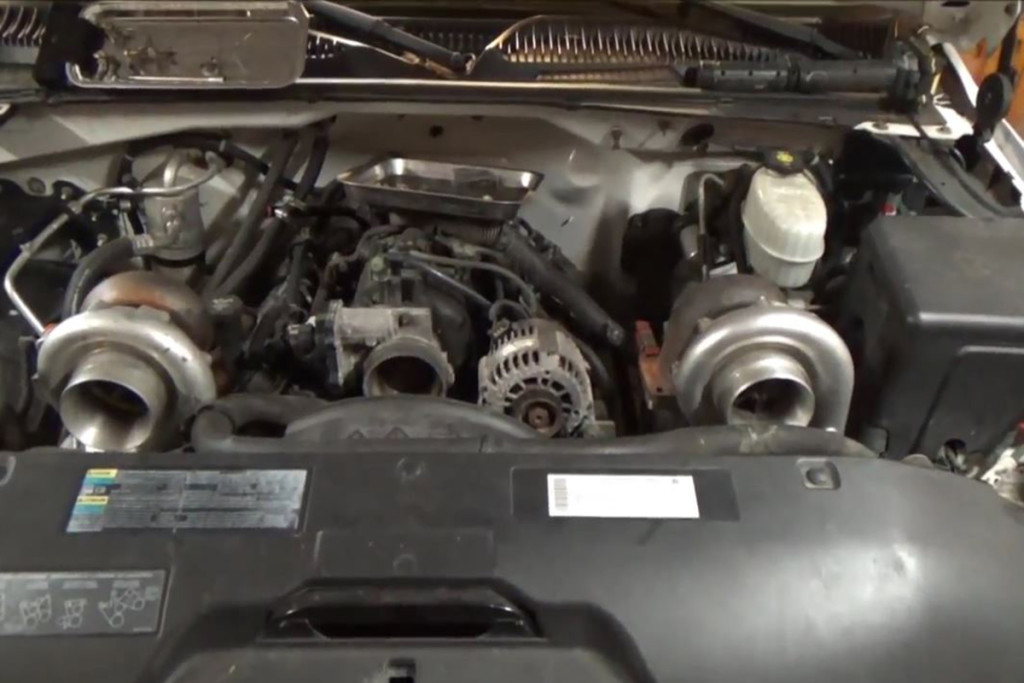

Craig recently went out and picked up a 2004 GMC 2500 HD with a six liter LS and a 4L80E automatic transmission because several of his customers were wondering what they should do to get more power and torque out of the engines in their GM trucks. The 4L80E was recently rebuilt and had a Trans-Go Transmission Correction Kit installed. He put together a series of videos to help you figure out one way to relatively cheaply turn that somewhat boring six liter into a screaming monster without the expense of rebuilding the engine.

This one’s got over 310k miles on the odometer, and all he replaced was the oil pump and the valve springs, which he only replaced because he ended up sticking two (yes, TWO) turbos on it. I’m going to walk you through the whole process he went through to turn this rather staid and laid back truck into an 800 HP monster. We’re going to do this as a three part series. This, Part One, will go into playing around a bit with the factory tune and then setting up the exhaust manifolds for a twin turbo setup. Part Two will delve into the intake, valve train, and fuel system upgrades required for an 800 HP twin turbo engine. Part Three will finish the build by finishing up the exhaust system.

How to Pick a Reliable High Mileage Junkyard Engine without Rebuilding It

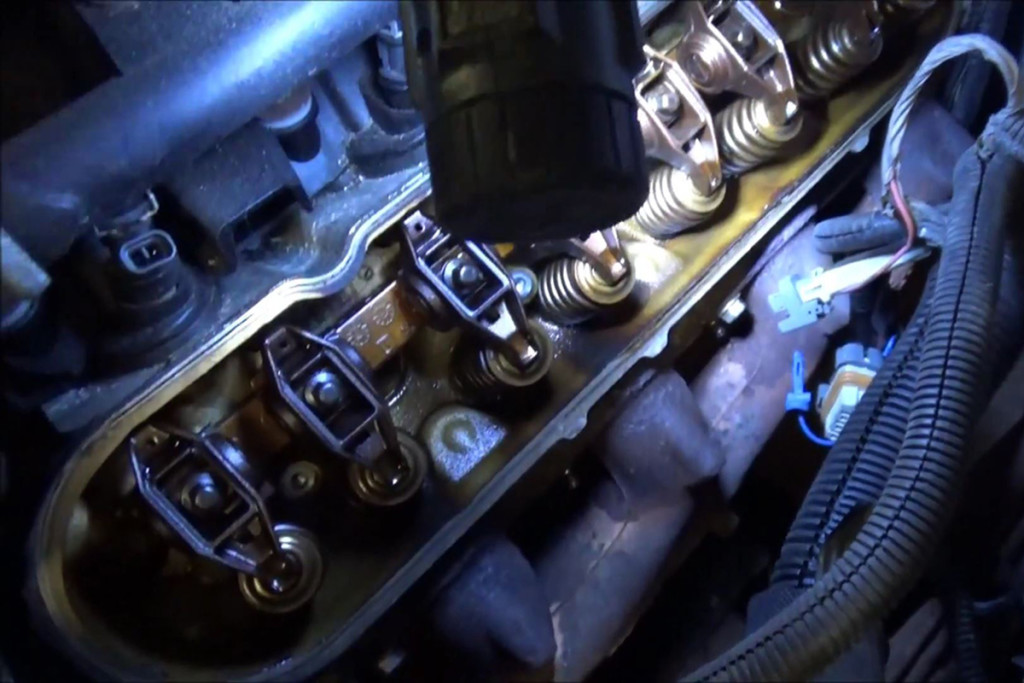

Us old timers would never think if picking up a high mileage engine that we were planning on building to pump out more than 700 horses without tearing it down and rebuilding it. Craig however, does it all the time. He’s got an in with the local junkyard and they usually don’t mind him pulling the valve covers to take a look inside, but he realizes that most junkyards won’t allow that, so he gives us other ways to check to see whether or not the engine is worth our time.

If the junkyard won’t let you pull the valve covers, Craig says to open the oil filler cap and shine a flashlight inside. His best tip is to check the heads between the cylinders. You should see a nice gold-ish color and not find any sludge. If the engine looks like this, you can be almost 100 percent certain the rings are good. If you’re looking through the oil filler cap, use a long straight screwdriver and lightly scrape the top of the head with the blade. If your fingernail or the screwdriver blade came up with sludge, find another engine; that one either had terrible maintenance or has bad rings.

Dropping ¼ Mile ET by Three Tenths of a Second with Computer Tuning

The first thing that Craig did was take a couple passes down a street near his house that’s he’s got marked off for a quarter mile. Usually he goes to the track nearby for this, but he started this project at the beginning of last winter and the tracks in the area were closed. His best “pass” was at 16.5 seconds and 86 miles per hour (MPH).

Next, he downloaded the factory tune from the truck’s computer and tweaked with the torque and transmission management a bit. This netted him an ET reduction of two tenths of a second down to 16.3. He knew he could do better, so next he manipulated the timing tables and did some more massaging of the torque management. This came up with another tenth of a second in ET reduction with a speed of 89 MPH.

Mind you, this was done without using a wideband and without locking up the converter. He simply stabbed the pedal and went. When he started out, he’d get a very slight chirp out of the rear wheels at launch. By the time he finished massaging the ECM, the wheels were breaking loose very satisfyingly. It must be remembered that he accomplished this with stock tires for the GMC pickup that were extremely worn. He figures that these mods alone would make the truck run in the high 15-second range if he had better tires and a true track with good grip to run on, as well as a more reliable timing system.

Setting Up the Manifolds for a Twin Turbo System

Craig reminds me of some of the best teachers I’ve had throughout my life. Not only does he tell you what he’s doing, he explains why. He also encourages his clients to take leaps they normally wouldn’t because he knows that they can do what he does (to an extent) if they only believe in themselves. If you’re setting up your own turbo system from scratch, Craig recommends picking up one of Summit Racing’s Universal Exhaust kits. This will have more than enough for you to complete the installation of a complete twin turbo system. He recommends at least a 2.5 inch kit to ensure adequate exhaust flow.

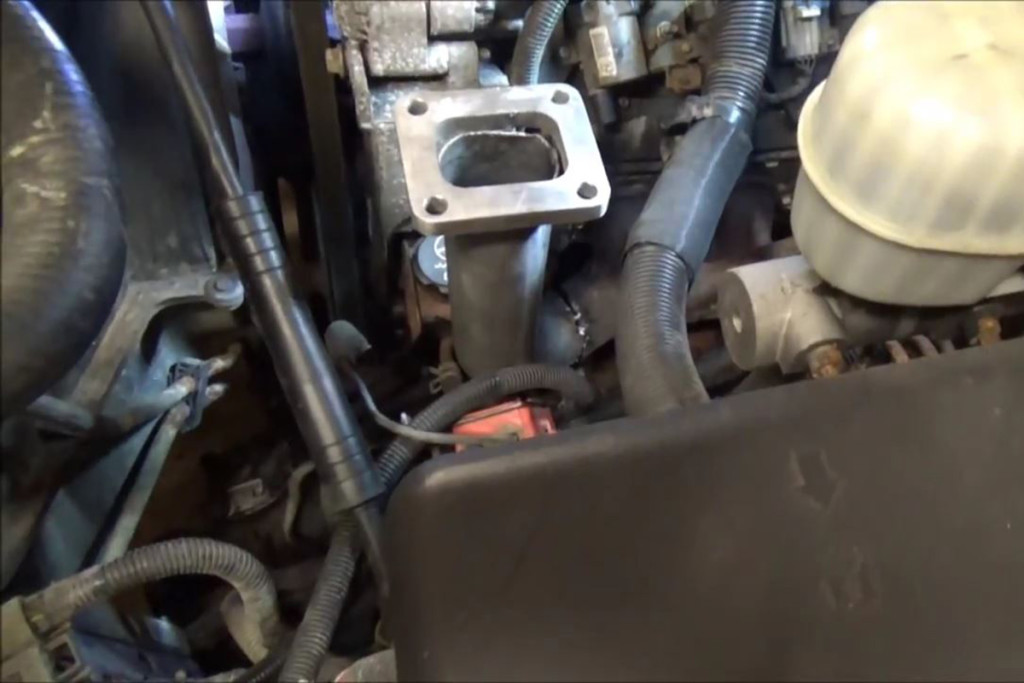

In setting up the manifolds for the twin turbo setup, he gives us a couple of different options. The first option is to unbolt the exhaust manifolds and simply flip them over, putting the outlet and flange towards the front of the engine instead of the rear. However, he doesn’t usually like doing this because it usually puts the plug wires too close to the very hot exhaust manifold. What he prefers is to swap sides with the manifolds, leaving the plug wires plenty of room.

In this particular build, he does both. He swaps the passenger side manifold to the driver side and used a second passenger side manifold that he had in a “leftover parts” pile-you’d have to go get one from the junkyard- and flipped it over, pointing the exhaust flange towards the front and up.

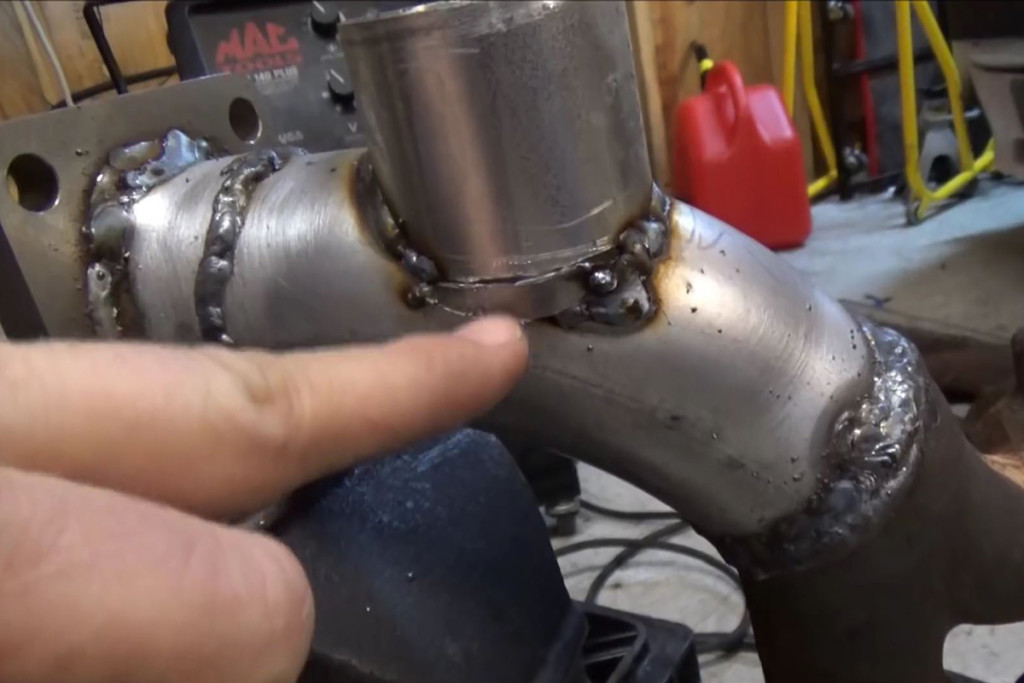

The next step is cutting the flange off so that the pipe that the turbo (T4) flange sits on can be welded on. For those that haven’t done much if any welding and don’t own a welder, Craig recommends going to ebay and picking up a small 110 MIG welder. There is no hard and fast rule as to where the turbos have to go. The only thing you have to be sure of is that there are no leaks.

Get as much out of the way as you can: Wires, hoses, piping, etc. You want a clean and open space to work in. Eyeball where you want the turbos and measure. Then measure again before cutting. Picture how things are going to look in your mind before cutting anything. To get the height for the flange correct, I recommend hanging something across the engine bay supported on the fenders and measuring down to where you want to mount the T4 flange for the turbo.

The hard part here, even for people that have a bit of experience with a welder, is filling the gaps between the pipe and the manifolds that are inevitable. Craig and I both recommend practicing with some scrap pieces before diving in and welding on the parts you’re going to use. Teach yourself how to “burp” the welder to fill the gaps. If needs be, cut a piece of scrap in the shape of an eyebrow and use it to cover the gaps. When doing this, you need to make sure that you leave enough pipe between the manifold and the T4 flange to mount the wastegates.

Of course, if you’re building a show car or truck, you’re going to want to be as careful as you can and match the angles you cut on the pipe and exhaust flange perfectly. Also, don’t worry if your welds look “fugly.” Those down by the exhaust flange will be, or should be, covered with header wrap.

Mounting Up the Wastegates

As long as the engine is running, the turbos are producing power. Because of this, we have to put a wastegate between the merge and the turbo. In a twin turbo system, this means that we need to put one between each manifold and each turbo’s T4 flange. You need to make sure that the wastegate is installed in such a way as to ensure that you’ve got access to install the dump tube outside of where the spent exhaust gases it vents can be picked back up by the turbo. Dyno and tuning guys will tell you that not doing so will rob your engine of at least 100 HP because you’re making the engine burn exhaust gases instead of oxygen.

Cut a section of scrap exhaust pipe. We’ll call this the wastegate pipe. The length doesn’t matter. Hold your length of pipe against the section of manifold pipe between the manifold and the T4 flange and mark the pipe with a felt tip pen. Remove the manifold and use a hole saw to cut the opening for the wastegate pipe. You should smack the center of this circle with a center punch to keep your drill from drifting.

Smack the wastegate pipe into this hole until your desired angle is reached. Mark the sides of it with your pen. Remove it and use a cutoff wheel or tin snips to cut the extra metal off so the wastegate pipe fits nicely against the manifold pipe. Carefully tack the two pieces together and then run a continuous bead to ensure a gas tight seal. Again, any gaps between the sections can be filled by “burping” the welder or covering with a scrap piece cut to fit. Once the wastegate pipe is welded to the manifold piece, reach in with a grinder and smooth the edges to ensure smooth flow of exhaust into the turbo and wastegate.

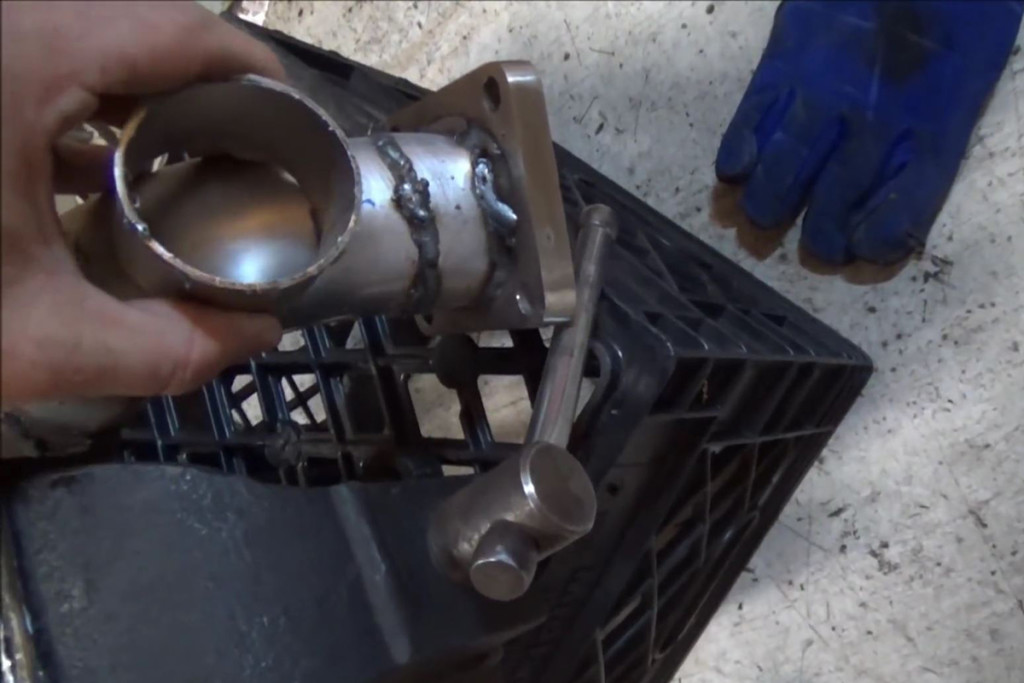

When you open your Justin Sane Racing Products Universal Turbo kit, you’ll notice that the opening on the turbo flange is oval, whereas the pipe you welded onto the manifold is round. Grasp two opposing sides of the pipe in a clamp just tight enough to secure it. Then squeeze the other two sides in a vise to make the end of the pipe oval. Fit the pipe to the flange and fine tune the oval you’ve created so it fits the T4 as closely as possible.

Once this is completed, tack the flange securely to the pipe. Find the side that fits the closest and run a bead. With the pipe still hot, use a drift punch or something similar to punch the pipe around the inside of the flange in the corners to get the closest fit and smallest gaps possible. If you do this right after welding up a seam, the pipe will fit in easier because it will stretch to fit the gaps.

Our final step is the dump tube. This is the tube that the excess exhaust pressure from the manifold is released through. Craig usually likes to route this into the fender well as this ensures that the turbo can’t suck those exhaust gases back up and ruin performance. If you want, or if your state requires all exhaust gases be routed through the catalytic converters, instead of dumping into the fender well, you can route the dump tube to the cold side of the exhaust after the turbo(s). It’s up to you.

If you need any more advice or help, or would like to order a universal turbo kit with almost everything you need for the install instead of having to buy a variety of parts from somewhere like Summit or Jeg’s, you can hook up with Craig either at the link above or on his Facebook page. I know he’d appreciate it.

Stay tuned. Part Two of this three part series-The Fuel System and Valve Train is next.

Leave a Reply