Part II: Picking the Power Parts for the Bottom End

In the last segment of our hypothetical LS motor build, we picked the parts for the top end. This time we have to “contain” the carnage with the bottom end of the motor. Now, we’ve referred to the bottom end as a place that isn’t as responsible for power production when compared to the top. That still holds true, but you can still make extra power (sometimes a bunch of it) downstairs with wise component selection. Besides, picking the right parts sure does help when it comes to reliability.

One of those places, believe it or not is the cylinder block. Case-in-point is Dart Machinery’s LS Next cylinder block. The LS Next block is a significant departure from the norm in the bottom end of the LS engine. By eliminating the “Y-block” layout and incorporating conventional style main caps along with conventional oil pans, Dart addressed the various issues that came from the LS motor’s separated crankcase bays. Windage is greatly reduced. The result is increased power and improved lubrication.

This LS Next block has main webs that are significantly stronger due to the elimination of the bay-to-bay breathing windows. Eliminating the windows allowed the cylinder barrels to be extended 0.3750-inch deeper into the crankcase. This makes for superior piston support at the bottom of the stroke. Conventional style 4-bolt steel main caps are used. The full deck design measures 0.625-inches with six head bolts per cylinder. Dart also increased the head-bolt size to 7/16-inch. The head boltholes are blind, meaning that they don’t extend into the water jackets. Dart’s priority main oiling system ensures high rpm reliability and includes a provision for oil restrictors in the lifter valley. Maximum bore is 4.220” for iron blocks (which we’re using) and 4.165” for aluminum blocks, or you can get an optional Darton M.I.D. sleeve kit allowing up to 4.220” bore on the aluminum block. For our hypothetical build, we’ll take the engine to 4.1275-inches in bore, which in turn leaves plenty of room for rebuilds down the road. FYI, the blocks come 0.010-inch undersize in the bore size, which allows for honing and piston fit. And by the way, aside from some select bottom end bits (oil pan, etc.) and the larger head bolts/studs, most stock and aftermarket LS components can be utilized. Dart’s part number for the big bore iron block is 31837211.

For the crank and rods, we’d go straight to Molnar Technologies and order a 4.00-inch stroke LS Crank (part number 346-4000LB6F-610). These 4340 forged crankshafts are heat treated to increase tensile strength, shot-peened to increase fatigue life, nitrided for wear resistance and 100% mag particle inspected to insure against cracks. The critical sizes on the crank are held to extreme tolerances too. Bottom line here is, this is a stout piece you can count on.

We’ll include a 6.125-inch long H-Beam rod from Molnar Technologies. Their lightweight rod (part number CH6125NLB-LS8-A) weighs in at 602 grams. They’re manufactured from 4340 billet material, heat treated to increase tensile strength and are shot peened to increase fatigue life. All rods have a wear resistant bronze bushing for long wrist pin life and feature ARP2000 series fasteners. All Molnar Technologies connecting rods are finished in Michigan. Sizes are held +/- -.0001-inch (yes, that’s taking it to the extreme). The truth is, Tom Molnar knows cranks and rods. It shows in his products.

Pistons, pins and rods for our paper build are out of the CP Bullet catalog. Pistons are CP part number BLS1114-0025. The pistons have a bore of 0.1275-inches and are designed for use with our 4.00-inch stroke crank and 6.125-inch long (center to center) connecting rods. They have a compression height of 1.181-inches. The pistons are flat tops with 4.6 cc’s of valve notch(es). They’re setup for 1.5 X1.5X3.0-mm rings (which we’ll source from CP) and the wrist pin is a 0.927 X 2.250-inch job (supplied by CP). Finally, the pistons are manufactured from 2618 alloy.

Given the different bottom end layout of the Dart LS Next block, a different oil pan is required. Moroso has the application covered with a very slick aluminum pan complete with billet aluminum spacer rails and a complete fastener set (part number for the pan is 20144). The pan fits most vintage Camaro-Chevelle-Nova and G-body chassis. Moroso also offers a high flow wet sump pump for this engine (part number 22120) along with a special pickup (part number 24144).

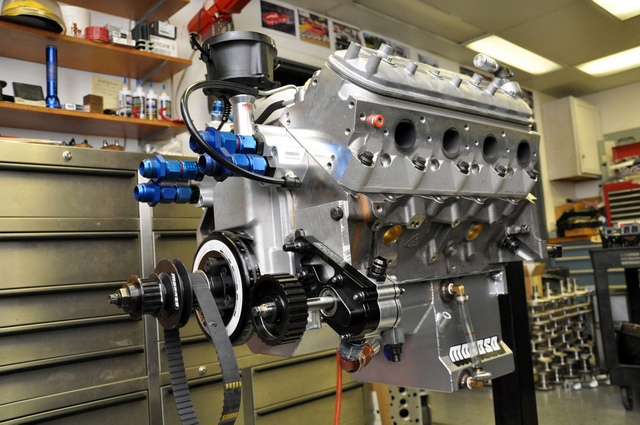

So far so good. Next up we’ll need some additional hardware to make the motor run. ARP offers a complete array of hardware for the LS (including Dart’s LS Next block). We’ll use ARP parts exclusively in our hypothetical build. We’ll also need a timing chain package and Cloye’s Billet Single Roller is perfect. Part number 9-3672TX9Z is a three-bolt, single roller (extreme duty “Z” chain) based upon a set of billet gears. It’s adjustable (nine keyways) and includes a chain damper. A damper (harmonic balancer) is also required. We’d use an ATI # SK286S setup for a wet sump motor. This particular damper is designed for use with a serpentine belt.

The final big accessory we need (not counting water pump and drives which are pretty much car specific) is the ignition. These engines are distributorless (eight coil jobs). We’d use a Chevrolet Performance LSX ignition controller for a crank with a 58X reluctor wheel. The internal software allows for custom vacuum advance curves, timing curves, a programmable rev limit, and so on. To round it out, we’d need a set of coil packs. Chevy’s #19257878 fit the bill perfectly. Besides, they’re designed specifically for this application.

That’s pretty much a wrap on the bottom end of our engine. Next time around, we’ll fire up our hypothetical dyno (dyno simulation software) and see how the beast runs. You might be surprised! Meanwhile, check out the accompanying photos for more info:

(credit Dart/Moore Good Ink): At first glance, this Dart block looks like a generic small block casting of some sort. But look closely. It’s an LS block without the skirt (basically, much like a small block Chevy).

(credit Dart/Moore Good Ink): Upstairs, you can see the LS architecture. The second photo (obviously) shows you a ¾ view of the casting. It’s a very nice piece, and Dart accomplished some amazing things with this block (see the text).

(credit Molnar Technologies): If the block is the foundation of the engine, then the crank is the heart of it. Here’s a look at our 4.0-inch stroke 4340 crankshaft from Molnar Technologies. Tom Molnar is a very well respected (and seasoned) industry insider. This is his take on the LS platform. We’d specify a wet sump snout. Rod pins measure 2.100-inches and the bob weight is 1800 grams. Note the 58-tooth reluctor included in the crank. Like the other parts selected, this is very, very nice (state of the art) piece.

(credit Molnar Technologies): Molnar Technologies builds a fabulous H-beam connecting rod for the LS power plant (they actually have multiple choices). Our choice is a 6.125-inch center-to-center job with 7/16-inch ARP fasteners and a bronze bushing upstairs. This is a 602 gram rod, and it’s pretty much perfect for a normally aspirated application.

(credit ATI). The engine needs some form of harmonic damper (balancer). For this application, we went straight to ATI for one of their LS7 wet sump style pieces. Note that the damper is setup for a serpentine accessory belt drive.

(credit Moroso Performance): To button up the bottom end, we’ll need a pump, pan and pickup. Moroso has come up with a complete package that fits the LS-Next block. It’s a very nice high quality setup and like the rest of the parts, it’s readily available (direct from Moroso or from your favorite speed shop). By the way, note the louvered windage tray. This thing was engineered from the start to eliminate oil starvation and at the same time, dramatically reduce windage.

(credit Cloyes): We’ll need a timing set to hook the crank snout to the cam. We chose a singe roller (“Z” style chain) from Cloyes for this application. It includes a nine-position billet lower gear, a billet upper gear and a chain damper. FYI, most aftermarket cams are setup for three cam bolts, not the single bolt arrangement found on some LS motors.

——————————————————————————————————————————————————————–

So You Want to Be A Drag Racer: Buying, Building, Wrenching and Racing

The allure of the drag strip is easy to understand – a place where it takes less than 10 seconds to make a stand, prove your skill, speed, and nerve. But the road to the races can be intimidating. The Burnout wants to make that road a lot smoother for aspiring racers, whether it’s through building a new car, modding a used one, or taking that ride all the way up to the burnout box and beyond. This series is a work in progress, an ever expanding comprehensive guide to all the things that take drag racing from concept to reality.

Want to chat about this on social media? Use #RJDragRace on Facebook or Twitter

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.2-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.3-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.4-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.5-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.7-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.8-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.10-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.11-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.12-150x150.jpg)

![[Drag Race 101] Building an LS Bracket Motor from Scratch Part II](https://www.racingjunk.com/news/wp-content/uploads/2014/07/Parts-2.13-150x150.jpg)

You seem confused so let me help you out its a engine its not a motor, you show your confusion where you say motor 3 times then you say engine, you mention Dart so I went to their site and no where do they refer to a engine as a motor Dart uses the correct terminology, so I started looking at the GM service manuals and owners manuals that use the LS engine no where do they call it a motor they call it a engine even at the GM “engine plant” where they build their LS “engines” they never call them a motor, where you put the ‘motor oil’ into the LS engine the cap you remove it says “engine oil” read the bottle the ‘motor oil’ is for your engine not your motor.

The only place I see it called a motor is by all the hacks and quacks writing articles like like here, all the SAE papers, owners manuals, service manuals, tech documents written by manufactures all use the correct terminology “engine”

I know what it says in the dictionary so spare me thats not the real world where all the professionals are using the correct terminology, research this for yourself you will come to the same conclusion only the hacks and quacks are calling a internal combustion engine a motor.

Shame people writing articles trying to educate the general public cant even get the basics right.

I am not sure how you can read thousands of times ‘engine’ in all the official documents put out by the industry leaders who define it clearly in their documentation then start typing out “motor” makes me wonder about your attention to detail when your typing out a list of parts your trying to get me to purchase for my ENGINE build.

Hopefully you and others will not close you mind because your some how offended by being corrected and do your own research, hopefully you wont look ignorant by standing by what the dictionary says because the engine industry clearly says they are wrong.

Straining at a gnat and swallows a camel.

…and as long as you’re doing so, learn proper punctuation if you’re going to post here.

Dart has come out with a Improved LS-Next-2 with 1/2 inch Head Bolts & Main Caps with 351 Cleveland size Mains & Thrust bearing.Now on Dart Website.