Don Schumacher Racing (DSR) and Motorsports (DSM) have joined the fight to help protect the brave health care workers putting themselves at risk to treat those suffering from COVID-19.

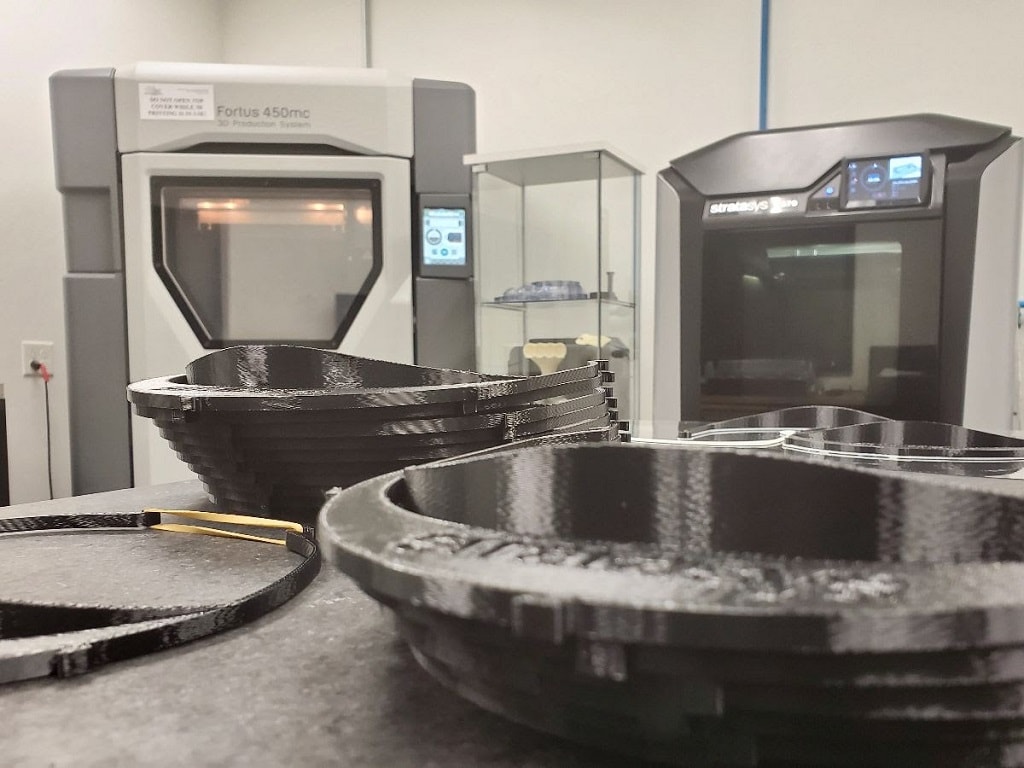

DSM has teamed up with Stratasys, a global leader in 3D printing technology, to help address widespread lack of supplies by producing headbands for medical face shields in healthcare facilities. DSM’s two Stratasys FDM 3D printers, the Stratasys Fortus 450mc and F370, are typically used for chassis fixturing, weldment fixturing, rapid prototype development and proofing out new components for DSR’s of race cars. With NHRA drag racing paused by the pandemic, both printers have been temporarily repurposed to produce as many headbands as possible.

“We take this pandemic very seriously and want to do our part to help,” said DSM owner Don Schumacher. “When our partners at Stratasys approached us about producing these crucial pieces for medical face shields, we didn’t hesitate to say ‘yes.’ We have the capability, so of course we wanted to do whatever we could to help support the vulnerable medical personnel that are working so hard during these unprecedented times. A huge thank you to Stratasys for leading this initiative.”

The completed DSM-produced headbands are given to Stratasys, where clear shields are added to the bands. The finished shields are put into inventory at the Stratasys warehouse, then distributed to hospitals upon request via an online request form.

“The response from the staff at DSM for the Stratasys COVID-19 face shield initiative is greatly appreciated,” said Allen Kreemer, Stratasys’ Senior Strategic Applications Engineer, Americas. “DSM has put its state-of-the-art manufacturing facility to work in record time, producing face shield frames that will be used to protect many healthcare workers. DSM continues to redefine the meaning of the word ‘partner’ during this challenging time.”

Great job DSR.

it would be a lot quicker to die cut from one piece of transparent thin lexan with heat bent hooks at the rear for the rubber band and three blocks of neoprene foam attached with double sided tape to the forehead area. This is not a criticism of the work being done rather a look at a sharper way to produce enough rapidly and cheaply. Hot rodders everywhere should be turning their minds to solve these sorts of problems. Beauro rats certainly dont have the ability!