In our last issue, we examined MSD’s unique Flying Magnet crank trigger system. If you recall, it’s based on four magnets embedded in a larger diameter trigger wheel. The magnets pass by a non-magnetic pickup, which triggers the ignition signal. A flying magnet layout is much more reliable when compared to other systems since it cannot be falsely triggered by bolts, race track debris or engine vibration.

You’ll also recollect that the distributor’s job is simply to provide a place for the coil to “distribute” the spark energy to the respective spark plugs. By design, the distributor cannot have an advance mechanism – it must be locked out. As we mentioned in that earlier article, you can weld up the advance mechanism or bolt it down to disable it. There’s another option – use a dedicated crank trigger distributor.

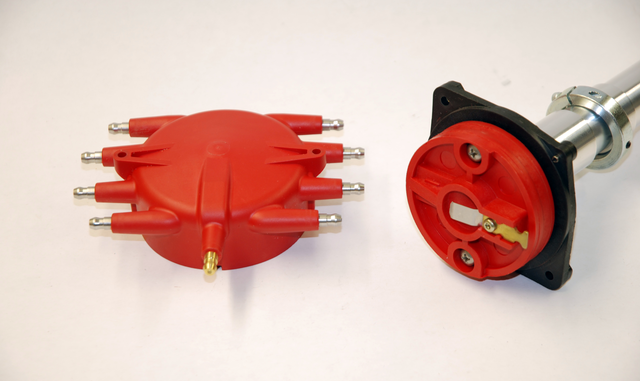

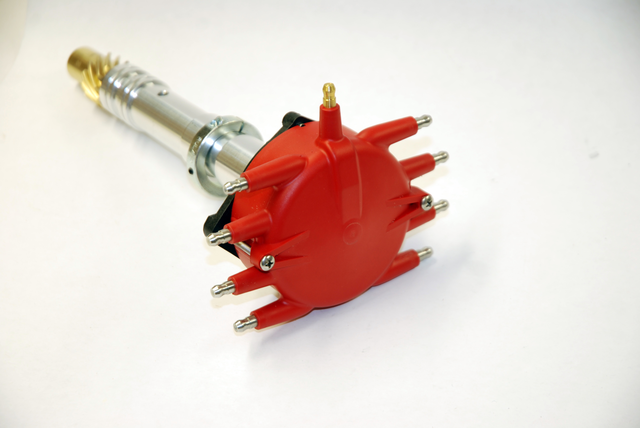

MSD’s version is built specifically for racing engines and in the design; they considered that many of those engines had limited room for the distributor due to large tunnel ram intake manifolds or blowers. The distributor is equipped with a special low-profile crab style distributor cap to allow it to fit in extremely tight areas. The small, low crab style cap is a custom MSD design (not adapted from another application), and as you can see in the photos, it incorporates spark plug-style terminals. The cap is molded from a strong, durable Rynite material. The rotor is also a custom design, also molded from Rynite and is built with a large (heavy duty) brass tip. The rotor tip is secured with a screw for high rpm racing applications.

Like other MSD distributors, the body is CNC machined from a chunk of billet aluminum. The housing is designed to accept a pair of O-rings at the bottom that improves oil control by preventing oil pressure loss (using the O-rings is up to you and/or your engine builder). In addition, MSD machines a small oil bleed hole in the base. The purpose? It’s engineered to spray oil on the distributor and camshaft gears to prevent excessive wear. MSD includes a slip collar with the distributor. The slip collar is adjustable up and down on the body. This allows you to make up the difference in deck heights on a modified engine, which in turn allows you to set the gear mesh (cam to distributor) and oil pump drive shaft engagement.

In order to adjust the slip collar, first, loosen it, and insert the distributor into the engine until it bottoms out against the oil pump drive. Once it bottoms out, raise the distributor 0.010 – 0.030-inch, and then slide the slip collar down into the position and tighten it.

At this point, you can check the oil pump to check the pump drive shaft engagement along with gear mesh. According to MSD:

“Coat the distributor gear with moly grease and install the distributor. First, measure the distance between the base of the slip collar to the tip of the distributor shaft. Then with a straight edge, measure the distance from the intake manifold distributor flange to the top of the oil pump intermediate shaft. Take the two measurements and subtract them. The difference is the overlap. The tongue of the distributor shaft should fit in the groove of the oil pump shaft by at least ¼-inch. If there is not enough clearance or too much clearance, a different oil pump shaft is required.”

“Next, crank the engine over several times. Before pulling the distributor out, make sure the rotor is in the position that lines up with the original removal mark. Then pull the distributor out and inspect the gear pattern shown on the grease. The proper mesh will leave an even pattern in the middle of the gear. Adjust the slip collar to obtain the correct mesh.”

As pointed out in the earlier article, the distributor in a crank trigger does nothing other than distribute high power spark from the coil to the spark plugs. You don’t move it to time the engine with a crank trigger. Instead, the crank trigger pickup is adjusted (up or down) in order to set the timing. But what is important with the distributor is to ensure that the rotor is phased correctly in relation to the distributor cap terminals. MSD has a detailed Tech Bulletin on this topic, but the idea is simple: The rotor tip should align with a respective cap terminal when the spark occurs. A cut away cap is used along with a timing light to check the phasing. In a crank trigger application, this is simple because there is no advance mechanism. All you do is rotate the housing until the rotor tip is in the correct position.

In the end, it’s easy to see that the distributor is a definite time saver and a problem solver when it comes to setting up a crank trigger fired ignition system. It also offers an advantage in terms of clearance, along with plug wire routing. In the next issue, we’ll look at one more option, and that’s a belt drive distributor. In the meantime, check out the accompanying photos:

Good article except the captions on the pictures have no correlation to what the picture is about.