Holley Annular Question...?

#11

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

Originally Posted by jmarksdragster

At 4000 RPM are the secondaries even open? I would still plug the secondary PV and jet up. Put an 8.5 PV in the primary, if it still appears flat try a 9.5. It needs to open when the load is high enough to warrant the extra fuel. And don't worry about any effect on idle, the idle jet is much smaller than the main jets feeding them. As far as the sputtering at 1600, have someone hold it there and cover one of the idle air bleeds, if it gets better try covering two. That would tell you the IAB/IJ sizes are too lean for the transition circuit and need to be changed to enrich the circuit. If it gets worse, then it is too rich. As far as the idle, pull the carb now that the idle speed is set and see how much of the transition slot is showing. should have roughly .020 exposed with the blade set for the correct idle speed. What kind of timing curve do you have? Insufficient initial timing will make tuning harder and will run poor, with that much cam I would expect a minimum of 20˚ initial, and maybe up to 25˚

Just wish I was further along with this 850 vs where I'm at > not much boating time and with the season coming to a quick end, I may only be out 2-3 times more.

At 4000 I would think I'm into the secondaries > at least some, but don't know for sure.

Question > if the carb is into the secondaries, what would be the reason to go higher w/PV on the primary side? Unless you're thinking the secondaries are still closed? My concern would be overly rich at cruising rpm's 3-4000

I can certainly block the secondary PV but let me ask you this > (if) the 6.5 isn't opening until some 4800 RPM why not just leave it and still raise the secondary jets to maybe 86?

I will pull the carb tomorrow to have a look at the transition slot.

Timing > I'm running a MSD RTR dizy > if memory serves me I'm a little conservative on total timing > 32* with 12-14 initial > all in @ 3000 rpm.

I can take it to 35* total but would need to change out the advance springs for your suggested 20* initial > just hope it doesn't bump against the starter when starting hot.

I went a little conservative on total timing for fear of detonation.

Question > conservative timing would lead to higher vacuum readings, correct?

Again, thanks for your time and feedback, Ray

#12

The reason for the higher PV is to supply fuel once the load is high enough to warrant it. Of course you have to change it to see where it needs to be for your engine to get the best performance.

As far as timing, you need to look at the plugs to see what it wants for timing, being too conservative will lower vacuum and create more exhaust heat do to fuel burning outside the engine. With the timing correctly set, it will burn the air/fuel more completely and at the time needed to have the greatest cylinder pressure when the piston can do the work most efficiently, allowing for smaller throttle openings for the same power creating more vacuum. Without O2's reading the plugs are even more important as they are your biggest tuning tool. Sneak up on it a little at a time, but I would expect 36-38 to be closer to optimum for you. It's usually high efficiency heads like GM's Vortec or like my SB2's that live well at lower timing, my SB2 runs best at 29˚.

As far as timing, you need to look at the plugs to see what it wants for timing, being too conservative will lower vacuum and create more exhaust heat do to fuel burning outside the engine. With the timing correctly set, it will burn the air/fuel more completely and at the time needed to have the greatest cylinder pressure when the piston can do the work most efficiently, allowing for smaller throttle openings for the same power creating more vacuum. Without O2's reading the plugs are even more important as they are your biggest tuning tool. Sneak up on it a little at a time, but I would expect 36-38 to be closer to optimum for you. It's usually high efficiency heads like GM's Vortec or like my SB2's that live well at lower timing, my SB2 runs best at 29˚.

#13

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

Carbs off > transfer slot showing appears to be a heavy .025 I took a few pics too.

Ordering a PV block-off for the secondary and a 8.5 PV for Monday.

I'll up the total advance to 35* and recheck all vacuum readings.

If you have a email address I'd like to send you a few pics.

Thanks, Ray

Ordering a PV block-off for the secondary and a 8.5 PV for Monday.

I'll up the total advance to 35* and recheck all vacuum readings.

If you have a email address I'd like to send you a few pics.

Thanks, Ray

#14

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

It's getting better > the flat spot is pretty much history.

I installed the primary 8.5 PV, jetted up to 81.

Secondary PV blocked, jetted up to 86.

Tested a nice long cruise at 3800/4000 rpm then shut down to read plugs > no fuel ring.

Then I did a few WOT passes again no fuel ring.

I'm thinking to throw more jet at it > maybe 84 primary and 90 secondaries.

Question, that slight miss at 1500 > when I placed my finger over one of the primary outside air bleeds, the stumble got much worse. What's that telling me??? Also, no brass inserts in the Primary outboard air bleeds.

Thanks for your feedback > and I also believe a 2" spacer may be in order.

Ray

I installed the primary 8.5 PV, jetted up to 81.

Secondary PV blocked, jetted up to 86.

Tested a nice long cruise at 3800/4000 rpm then shut down to read plugs > no fuel ring.

Then I did a few WOT passes again no fuel ring.

I'm thinking to throw more jet at it > maybe 84 primary and 90 secondaries.

Question, that slight miss at 1500 > when I placed my finger over one of the primary outside air bleeds, the stumble got much worse. What's that telling me??? Also, no brass inserts in the Primary outboard air bleeds.

Thanks for your feedback > and I also believe a 2" spacer may be in order.

Ray

#15

No brass on the outside bleeds? Have a picture? The outside bleeds are for idle and transition circuits, There has to be bleeds either on top if it is a factory Holley, if there were mods to it a restriction inside in the main body or the metering block itself. When you take off the front bowl, take a picture of both the surface of the block and the main body. As far as a fuel ring, you need a good plug magnifier to see it, and doesn't show well right away. You can look at the end of the plug for fuel as well, here is a picture from another site to show you.

#16

Saw the pics you sent, if those are the primary throttle blades, crack the adjustment screws on the secondaries open a little and bring your primaries back down just a tad, try to get the t-slots more square. Readjust the mixture, it will lean the idle a little. I see the missing brass, there still needs to be restrictions in the main body in the intersecting passage to where those brass inserts are missing, or in the metering blocks. Might be threaded, making changes if needed will be a little easier, just not as easy as on top.

#17

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

Originally Posted by jmarksdragster

Saw the pics you sent, if those are the primary throttle blades, crack the adjustment screws on the secondaries open a little and bring your primaries back down just a tad, try to get the t-slots more square. Readjust the mixture, it will lean the idle a little. I see the missing brass, there still needs to be restrictions in the main body in the intersecting passage to where those brass inserts are missing, or in the metering blocks. Might be threaded, making changes if needed will be a little easier, just not as easy as on top.

T-slots more square as in adjust the butterflies in the shaft? The pic may not show it well but both T-slots are exposed the same.

Your thoughts on a 2" spacer and if so any recommendations for manufacture?

As usual, great info.

#18

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

Originally Posted by jmarksdragster

No brass on the outside bleeds? Have a picture? The outside bleeds are for idle and transition circuits, There has to be bleeds either on top if it is a factory Holley, if there were mods to it a restriction inside in the main body or the metering block itself. When you take off the front bowl, take a picture of both the surface of the block and the main body. As far as a fuel ring, you need a good plug magnifier to see it, and doesn't show well right away. You can look at the end of the plug for fuel as well, here is a picture from another site to show you.

Since I switched to 20/50 synthetic oil I noticed a slight splash of oil around the base ring > this is why I was using a magnifier to look for the fuel ring.

Checked timing > 14 initial and 35* total. I could up the total advance to lets say 38* to see if it pulls any more RPM out of the engine.

Thanks, Ray

#19

On the underside of the base plate there should be flat blade set screws that affect the secondary opening amount. You can replace the screws with allen head set screws to allow adjustment from the top. T-slots square means they look like little squares at idle, as much exposed as they are wide. You can cheat the secondaries a little to allow the primaries to be closed more, the t-slot position has more of an impact on the primary side. If it reaches the point where they can't be closed enough, usually on an engine with a healthy cam, as long as timing is maximized you would need to add small holes in the butterflies to allow more air in at idle to allow the blades to be closed sufficiently at idle. Too much exposure will start drawing fuel at idle from the transition slots, and at some point will render the mixture screws useless. One thing that my help close them is initial timing, have you experimented with using more? I understand not wanting cranking issues, but if it will stand more initial it will have more idle vacuum and allow a smaller throttle opening, closing the primary blades and exposing less t-slot. Easy enough to bump up the timing to check idle to around 2000 RPM operation, once you find the most it will stand you can set the distributor curve to limit total timing to what the engine needs.

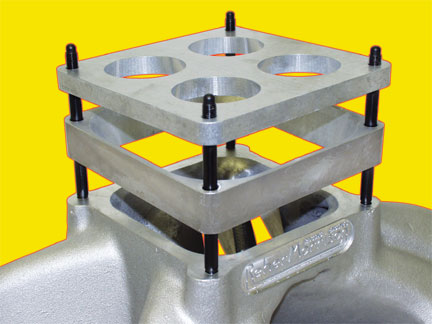

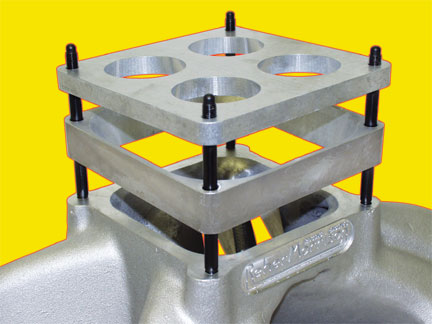

As far as spacers, they are usually a bandaid for some other issue. Intake plenum size too small or large, too much reversion from the cam or intake runner length incorrect. With that said, a lot of engines can improve from a spacer of some sort, unfortunately it a trial and error thing. If you have none to borrow and want to purchase something, I would suggest something like the anti-reversionary spacer below sold by Reher-Morrison. If it wants any at all it will probably gain with that one, and less likely to lose any. Available for 4150 or 4500 carbs. And if it does help, remember you are affecting the signal at the carb and may need a jet change.

As far as spacers, they are usually a bandaid for some other issue. Intake plenum size too small or large, too much reversion from the cam or intake runner length incorrect. With that said, a lot of engines can improve from a spacer of some sort, unfortunately it a trial and error thing. If you have none to borrow and want to purchase something, I would suggest something like the anti-reversionary spacer below sold by Reher-Morrison. If it wants any at all it will probably gain with that one, and less likely to lose any. Available for 4150 or 4500 carbs. And if it does help, remember you are affecting the signal at the carb and may need a jet change.

#20

Junior Member

APPRENTICE

Thread Starter

Join Date: Jan 2009

Posts: 22

Mark, thanks for clearing the confusion with this annular 850 and the many questions I have asked > and you have been more than gracious to answer

*I located the secondary adjustment screw however, I may not need to touch it.

*I now understand the "squaring of the T-slots"

*"spacers" I understand the bandaid comment > my way of thinking > being I'm using a dual plane intake for lower RPM throttle response and drive-ability 'maybe' a spacer will trick my Wieand Stealth to act more like a Team-G and add a little more RPM to WOT...no?

*or, would a Edelbrock Victor be a better direction?

Update from Thursday...

*the 1600 rpm miss is history as I simply turned out the idle mixture screws as you suggested.

*while out on the water, I rotated/advanced the distributor about the size of a pencil line.

*the results from the above were >>> I was able to back down idle RPM thus close the butterflies even more.

*the engine picked up 200 RPM up top > I'll need to put a dial-back light on it to see where total timing's at. It was 35* total, all in @ 3000 rpm.

*even with increases jetting > the plugs appear very white and again, not seeing any fuel ring way down low in the plug > I may cut one open to have a better look.

*I'll email you a few pics of the primary M-block and corresponding carb body surface.

*** I feel it's coming together quite well in small steps (like you said)...I would like to set total timing for the max RPM but > be cautious to make sure I'm not on the cusp of detonation.

*I located the secondary adjustment screw however, I may not need to touch it.

*I now understand the "squaring of the T-slots"

*"spacers" I understand the bandaid comment > my way of thinking > being I'm using a dual plane intake for lower RPM throttle response and drive-ability 'maybe' a spacer will trick my Wieand Stealth to act more like a Team-G and add a little more RPM to WOT...no?

*or, would a Edelbrock Victor be a better direction?

Update from Thursday...

*the 1600 rpm miss is history as I simply turned out the idle mixture screws as you suggested.

*while out on the water, I rotated/advanced the distributor about the size of a pencil line.

*the results from the above were >>> I was able to back down idle RPM thus close the butterflies even more.

*the engine picked up 200 RPM up top > I'll need to put a dial-back light on it to see where total timing's at. It was 35* total, all in @ 3000 rpm.

*even with increases jetting > the plugs appear very white and again, not seeing any fuel ring way down low in the plug > I may cut one open to have a better look.

*I'll email you a few pics of the primary M-block and corresponding carb body surface.

*** I feel it's coming together quite well in small steps (like you said)...I would like to set total timing for the max RPM but > be cautious to make sure I'm not on the cusp of detonation.