You’ve spent a couple/few thousand dollars on new engine internals, crankshaft, camshaft, pistons, bearings, etc. You’ve spent dozens of hours learning how to properly assemble those engine internals to get the best performance out of them. You’ve even bought matching heads, intake, and camshaft. You slap on that monster carburetor your “buddy” said you should get. You fire it up, and although the exhaust smells like it’s running a little rich (or lean), your “buddy” tells you that’s normal. You get it out on the track for a high-speed pass and the car doesn’t seem to perform, go as fast as you think it should.

Picking the Right Carburetor Comes Down to How Well Your Engine Breathes

That “running a little rich” smell should have been the giveaway for you. The key to carburetor selection isn’t “the bigger the better.” Not at all. The same can be said for the jets in the carburetor that control the flow of fuel to the engine. The key to proper carburetor selection is what’s known as “volumetric efficiency.”

That’s just a fancy term for how well the engine breathes-how well it gulps down air and, more importantly, how efficiently it can expel the exhaust gases in order to gulp down more air and fuel. The higher the volumetric efficiency of your engine, the larger carburetor you can stick on it. This is contrast to how correct fuel injector size is calculated, which is based upon horsepower output of the engine. Fuel injectors are said to support a specific horsepower output because they are rated by the amount of fuel they are capable of flowing per hour. Carburetors are rated by CFM, or cubic feet per minute of air they can flow. In other words: how well the engine and carburetor work together to breathe properly.

How Is Volumetric Efficiency Calculated?

Unless you run your engine on a dynamometer, volumetric efficiency is considered as a constant, it isn’t calculated. Volumetric efficiency is shown as a ratio. This ratio is the ratio of the amount of air (mass of air) taken into the engine compared to the amount (mass) of air that the engine displacement would normally/theoretically ingest with no restrictions or loss. As with other ratios, it is expressed as a percentage. Volumetric efficiency actually varies quite a bit over the operating range of the engine, with the ratio being pretty low at lower engine speeds (RPM) and climbing in conjunction with engine speed. When calculating volumetric efficiency, you should do so at the engine speed you expect to be hanging around at, otherwise known as the expected RPM of your engine application. This is typically the area or range in which your engine produces its peak torque output.

Although there are no hard and fast rules that can help you quickly and easily determine your engine’s volumetric efficiency, there are a few guidelines that can be used that are accepted in the industry. Your average street car engine, such as that in a Chevy Impala, has a nominal volumetric efficiency of about 80 percent, whereas an engine built to street performance specs, like those found in Corvettes and Camaros usually has a volumetric efficiency of about 85 percent. On the other hand, a bone-rattling NASCAR engine in Dale Jr’s number 88 Chevy SS operates at a volumetric efficiency of about 95 percent.

There Are Ways to Increase Volumetric Efficiency to Even Closer to 100 Percent

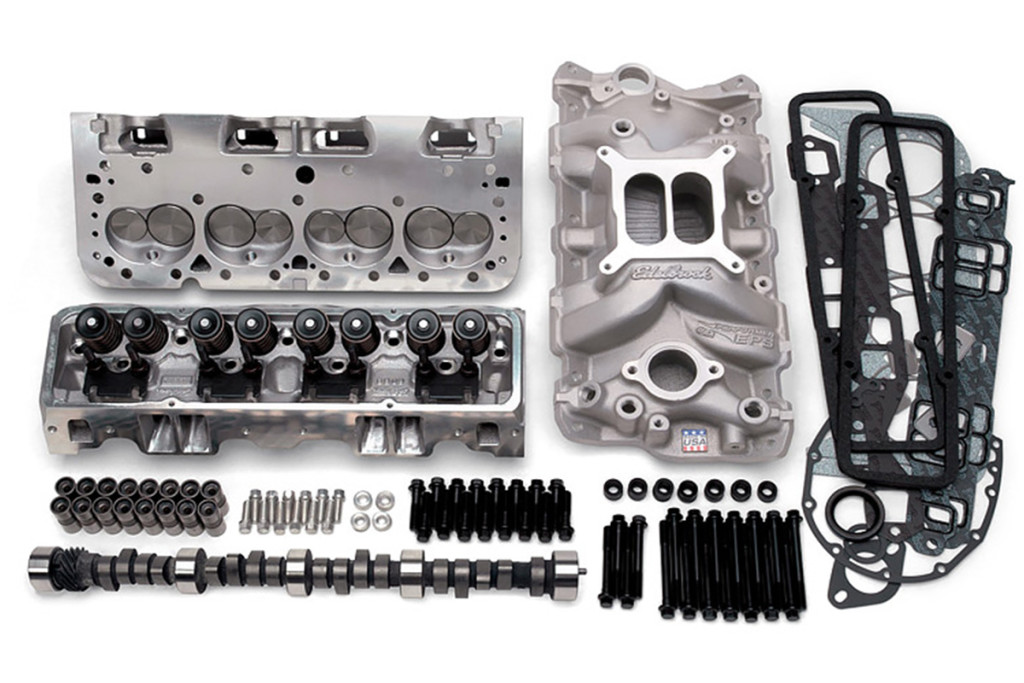

Remember up above where I mentioned that you may have spent several hundred dollars buying a matched kit including camshaft(s), cylinder heads, and intake manifold? Let’s say you picked up something like one of Edelbrock’s Power Package Top End Kits. These kits include timing gears and chain, specially-ground camshaft, cylinder heads, and intake manifold, plus all the required gaskets. All these components are carefully engineered and matched to perform as close to perfectly together as possible.

Now, if you send the intake manifold and heads off to an absolute genius at what’s known as porting and polishing, he can work some magic to make them flow air even better, to the point where theoretically they can have close to a perfect 100 percent volumetric efficiency. You see, even performance components have minor imperfections inside them that cause restrictions and interrupt the flow of air through the engine. Removing these imperfections will allow the air to flow better and increase the efficiency of the engine. Add in a really good aftermarket header system and you could theoretically have an engine with a 100 percent volumetric efficiency rating, or even slightly better.

Let’s Take a Few Examples

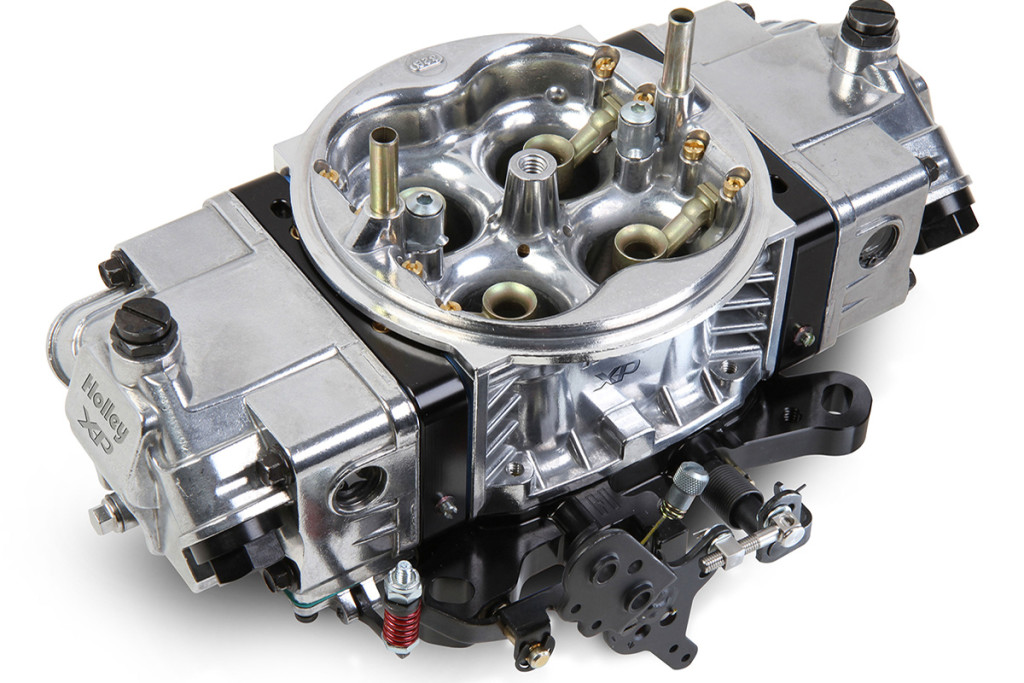

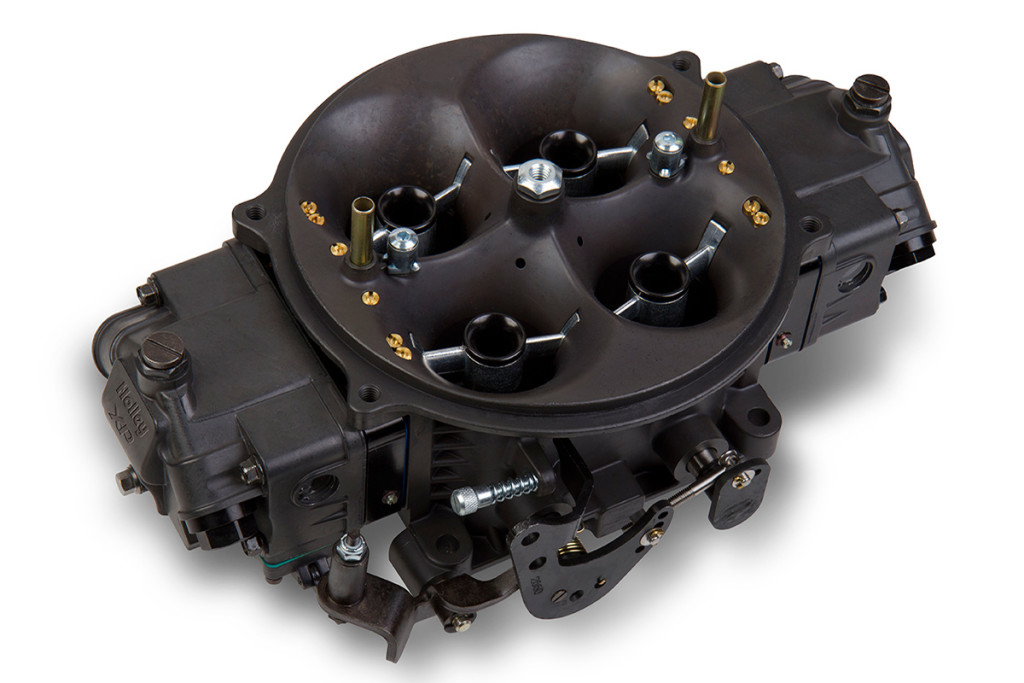

Holley Performance Products has been nice enough to explain all this and provide a chart that correlates engine speed, size, and air flow requirements. For example, let’s say we’ve got a built-up and almost perfectly tuned SBC 350 engine that operates at 90 percent efficiency. Let’s also say that we’re going to operate that engine around 8000 RPM most of the time. According to Holley’s chart, our engine would need just over 800 CFM of air flow to make maximum horsepower and torque if it operated at 100 percent volumetric efficiency. However, our engine only operates at 90 percent, so it only needs 90 percent of 800 CFM, or 720 CFM. We should always round down instead of up, so the we should choose a 700 CFM carburetor.

Let’s say we’ve built a big block, a 427 CID monster. We plan on running it at 7000 RPM most of the time. We installed the right components and it operates at 95 percent efficiency. It’s not on the chart, but it falls right between the 400 and the 450 that are on the chart. Again, we find that our engine, at perfect efficiency, wants just over 800 CFM of air, say 850 CFM. Our engine only operates at 95 percent efficiency though. 95 percent of 850 is 807, so we need a carburetor that flows 800 CFM.

Forced Induction Changes These Calculations Somewhat

Forced induction, whether turbocharging or supercharging, forces air into the engine, more air than would normally flow even with 100 percent volumetric efficiency. Most high-end engine builders will bump the engine’s airflow requirements by 20 to 30 percent for turbocharged engines. If the engine is supercharged, they’ll bump it between 40 and 50 percent. In other words, if we stuck a Roots 8-71on top of our 427 engine from above, we’d need about 50 percent more airflow. This means that instead of an 800 CFM carb, we’d now need our carburetor to flow 1200 CFM.

For the Cheaters/Math-Challenged Out There

I like math, but I know that not everyone does. Realizing that, I took a little bit of time and looked around for the best carburetor selection calculator I could find. I found this one at GT Spark Plugs. For their calculator, all you need to do is input your engine size, operating RPM, and volumetric efficiency (VE) and hit the Calculate button. 4SecondsFlat has a handy chart, if that’s too much work for you. They’re both pretty good, but the one at 4SecondFlat is a little more in-depth.

A Quick Word about Carburetor Jetting Before I Go

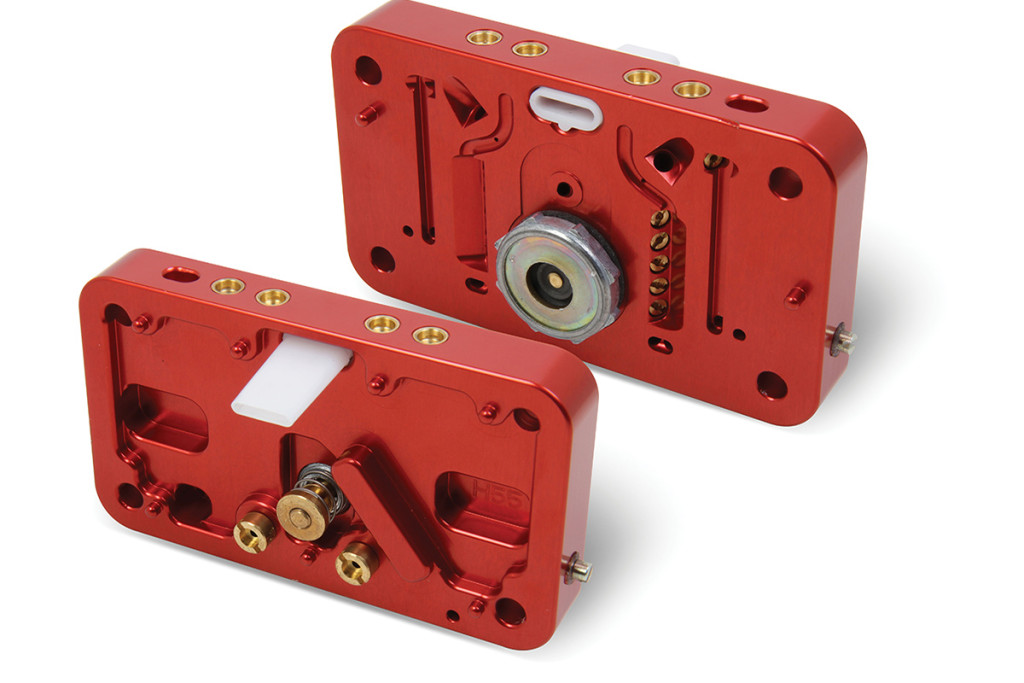

The jets in your carburetor are part of the control circuit for the control of fuel flow in the carburetor. They operate on a few principles, but the most important one is vacuum drop between the outside and the bottom of the throttle body/plate at wide open throttle (WOT). For the most part, the engineers that design and build carburetors know what they’re doing when it comes to selecting carburetor jets. This means that it’s highly unlikely you’ll ever need to change one unless they get gummed up really badly.

However, there are times, such as when you go somewhere like Denver, CO. for a competition, or you go from somewhere that it’s hot to somewhere that it’s cold, and thus has denser air, that you’ll need to consider a jet change. A good rule of thumb is if you’re going from dense air to thinner air, go down a size in jet size, and conversely, if you’re going from thin air to denser air, jump up one jet size.

My experience has informed me that playing with jets is just that, playing with jets. You’ll need to either be very careful removing and replacing the float bowls on your carb and should really think about replacing the bowl retaining screws with hex-head screws. Also, before performing any test (such as a three gas analyzer for combustion efficiency testing), make sure the floats are properly adjusted. Improperly adjusted floats will make moot every bit of your testing. I’ve been working on carburetors most of my life and I don’t mess with jets. If I feel I’ve got a problem related to jetting, I take my carb to an expert and pay them to deal with it. I highly recommend you do the same.

See you on the track and Drive It Like You Stole It my friends!

A good tune shop will have a 4 gas analyzer (CO, CO2, HC and O2). Setting the idle screws properly, and then running the rpm up to where it will be operated-SLOWLY to keep the pump(s) shots at a minimum, they can re-jet it to desired A/F ratio. It’s really no big deal til you start playing with the air-bleeds to obtain max hp at pull-over and varying rpms.

ok here goes, I have done a little class racing many more years ago than I would like to admit. I also did a lot of bracket racing for many years after class racing was beyond my financial resources. I am not making a attempt to discredit anything said here, but what I will say is tuning a carb is not a cast in stone one size fits all procedure.an example would be a 350 chevy that runs better with 780 cfm carb than the text book 600 cfm carb. I am sure my following comments will be responded to as a direct result of volumetric efficiency but here goes. Lets take our project 350 S10 to the track. Lets say we have a street strip set up flat top pistons and a set of vortech heads about 230-240 degrees [email protected] lets say about 500 +or – lift and a performer rpm intake.stage set. we have a set of common 1 5/8 tube headers and have all our engine stuffed down in our s 10 off we go to the track. funds ran out but we need to drive this thing before we just sell it. turbo 350 stock convertor and the stock 3.08 ratio ok here goes the carb comparison. we try the 4779 holley double pumper we took out of the box check the float level and give it a try.”the engineers” knew I was gona run this setup so the jets and all the rest of the tuning should be right. I smack the gas when the light turns green the truck falls flat on its face stumbles bad and if the engine doesn’t cut completely off it recovers and feels like it is towing a trailer until the rpms come up to about 3000 we install a holley 1850 585cfm vaccum secondary. the engine responds when we hit the gas at the line, it even pulls half decent, still a little dead at lower rpms but we just dropped a bunch off our et with a smaller carb. ok on the way home we get a scratch off ticket and win $5000.3 guesses where we are gona spend some money. but the engine is solid so we can leave it alone. we get a bolt in what ever rear ,9 inch ford seems to be the flavor of the day. we now have 4.10 gears, we decide to buy a convertor so we get a 10 inch advertised to stall 3500 rpms we are gona take buba with us to the track this time cause he knows carburetors and he has a whole box of jets cams and accelerator pump squirters and he said he knows how to use them. we get to the track and the truck leaves like a rocket feels great we are testing and tuning right.? buba has been on the tailgate of the pickup messing with the way the “engineers” had that 4779 double pumper set but what the heck it was a real turd anyway. he is changing thoses little plastic cams that actuate the accelerator pumps, you question him and he said lets try this carb again, you hesitate cause that carb was a turd buba said if it didn’t run better he would buy the pizza on the way home and if it ran better i would buy, so on with the 4779. well you guessed looks like I am buying pizza, then he looked at the time slip and asked if I wanted to make it double or nothing, he changed the jets and I was buying pizza twice. see I didn’t have a dyno, only a time slip. and anyone who think a out of the box carburetor works right on any combination, even the same design. like small block Chevy, has either been extremely lucky or has never been in the real world of poor boy racing .Buy the way, buba showed me a thing or 2 watch the mph on the time slip when increasing jet size go bigger a size at a time watching for mph increases when it slows a little go back a size. the folks with a lap top changing pulse width on injectors don’t know how easy they have it. there are many tuning parameters that will effect both cfm size and jet size in the same engine. a carburetor will never be anything more than a compromise of the ideal mixture compared to fuel injection

the 4770 is an 750

4779 forgive my bige fingers