What’s Best for your Small Block Chevy

Part XI; Rockin’ On – Can rocker arms affect power?

The rocker arms on your engine are nothing more than levers that simply open the valves. In stock form, your small block Chevy was delivered with rocker arms constructed of stamped steel that were more than adequate for a stock application, but what if things in your engine are no longer stock?

When building a performance engine, you will undoubtedly be turning a lot more rpm than the factory ever planned. By turning more engine rpm, you increase the amount of airflow that runs through said engine. More air makes more power—to a point. Moving more air requires a valvetrain that is up to the increased task, so you can expect to need; stiffer valve springs, stronger pushrods and yes, even better rocker arms.

With that said, an upgrade to aftermarket rocker arms is one of the first things that many racers contemplate. If you are thinking about a rocker arm upgrade, why not change the ratio of the rocker arms? Changing the ratio is a common modification that can actually get you a little more—and quicker lift out of a given camshaft profile. By increasing the ratio of the rocker arm, you actually increase total valve lift, and even the velocity at which the valves open and close. This actually increases volumetric efficiency to your engine and adds power. We’ve even run larger-ratio rocker arms on just the exhaust valves of some applications, to help get the spent gasses out of the engine.

Increasing the ratio of a rocker arm can be a great benefit for your engine, but keep in mind that the higher lift-ratio of the rocker arm can induce other situations that will need to be dealt with. For instance, by increasing rocker arm ratio, you might now induce coil bind in the valve springs, interference between the tops of the valve guides and the valve spring retainers, or even piston contact just to mention a few.

Upgrading to lightweight roller-tipped rocker arms is a great upgrade, but durability is also essential to prevent their failure. Roller-tip rocker arms reduce friction, which is a huge benefit in a high-performance engine. It is no secret that rocker arms have to be strong enough to handle the loads that are placed upon them. But did you know that manufacturer’s spend countless hours finding ways to make them as light as possible, yet strong enough to survive? Years of research have let them know that reducing the mass on the valve side of the rocker arm has more of a positive effect on reducing inertia than changing the mass on the pushrod side of the rocker arm? I know, you probably don’t care about that, but rocker arm designers do. By replacing the stock stamped or cast-steel rockers with aluminum roller rockers, you can figure on a gain of roughly 10 to 15 horsepower if utilizing the same lift ratio. It is possible to gain even more when installing a higher lift-ratio. The initial increase in power comes from the reduction in friction provided by the roller tips on the aftermarket rockers.

When choosing a rocker arm, there are many important factors to consider. Not to scare you, but choosing the right rockers will require some math skills, especially when changing the ratio. When making your choice, you need to take into account the rocker arm’s ratio that you are planning to use. The rocker arm’s ratio actually determines the maximum amount of total lift you will receive at the valve from a given camshaft. For example, a standard small block Chevy rocker arm is advertised as having a 1.5:1 ratio—it’s actually closer to 1.44, But I digress. If working with a camshaft that has .500-inch of lift, a 1.5:1 ratio will actually produce .750-inch of actual valve lift. Remember, the rocker arm gives 1-1/2 times the actual—in this case, .750 inch. As long as your push rods and valve springs can handle the pressure, and you have enough piston-to-valve, retainer and guide clearance, you’ll not have a problem.

When deciding on a rocker arm ratio, keep in mind that, while upgrading will get your engine more power, by choosing incorrectly, you increase the risk of parts failure. It is typically best to discuss your choice with your camshaft’s manufacturer.

Since a higher ratio will increase the camshaft profile’s actual numbers, it is also expected that you can increase horsepower, correct? Yes and no. If your camshaft is already too small for your engine, you can expect an increase in power. But, you might run into a problem whereas the increase in ratio causes a clearance issue. We’ve seen instances where the valve spring not only goes into coil bind, but the hole in which the push rod travels is not large enough, and the push rod contacts side of the hole. This is because the increase in ratio is done in part by the push rod cup being moved farther from the fulcrum in the rocker arm. If your camshaft is properly matched to engine’s combination, you might not see an increase in power at all.

An increase in rocker arm ratio from a 1.5- to a 1.6-ratio increases your valve lift around .030-inch. While .030-inch might not seem like very much, it can be catastrophic if valve-to-piston clearances are not checked. When checking piston-to-valve clearance, a minimum of .100-inch clearance for the intake valve and .080-inch for the exhaust is recommended.

Another clearance to confirm is retainer to valve seal. With your rocker arms properly lashed, (we discussed this in Part Ten), make sure that there is about .030-inch clearance between the spring retainer and valve seal with the camshaft at maximum lift. This can be hard to do with an actual valve spring installed, so using a height-checking spring makes the task easier. If you’re good at math, you simply measure the total clearance available with the valve closed, and then subtract your total valve-lift.

Checking coil bind requires that you know the installed height of your valve spring. To do this, subtract the known coil bind-height to find out how much lift your springs can take. Again, it is best to keep a minimum of .030 inch between a few coils if you want your springs to live a happy and long life. If you’re running a bigger diameter valve spring, make sure that your rocker arms don’t contact the retainers. If they do, you can install lash caps on the valve stem tips. Lash caps will raise the rocker arm away from the retainer. This doesn’t always work, but it might be an option. We’ve seen guys “clearance” the rocker arm, but this is not recommended, as you will weaken the rocker arm. There are also valve locks that place the retainer at varying heights, but that will affect your spring’s installed height.

To keep it simple, we recommend the use of die cast aluminum rockers when you are looking for a low-cost option that delivers better-than-stock performance. But, only use these when high pressure springs and/or high engine rpm are not going to be encountered. Use extruded-aluminum rocker arms when you are looking for a rocker arm that is a little more durable than die cast (especially when using higher spring pressures like in a street/strip application). Since extruded rockers are made from billet, there is little concern about porosity like might be found in a cast rocker. Most extruded aluminum rockers are available in a wide range of lift ratios, which gives you more options with camshaft selection.

This image show the difference in push rod location between a 1.5:1 ratio (left) as compared to 1.6:1 ratio rocker. If the ratio moves the pushrod this much, clearances need to be checked anywhere it could contact the cylinder head.

When possible, it is always best to use a rocker arm that is the recommended ratio for your particular camshaft. These Ultra Pro Magnums from Comp Cams carries the best stiffness-to-mass rocker they have ever created. Because of the arched nose, this stud-mounted roller rocker will offer much greater stiffness compared to other stud systems and provides another option in lieu of going with a shaft-mounted system.

An inexpensive upgrade is to get a stamped-steel rocker arm that has a roller tip. By replacing the stock stamped or cast steel rockers with aluminum roller rockers you can figure on a gain of roughly 10 to 15 horsepower with the same lift ratio. It is possible to gain even more with a higher lift ratio.

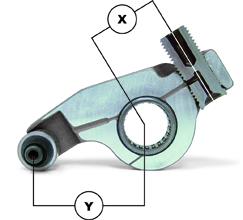

Figuring a rocker arm’s ratio is done by comparing between two points. For a 1.5:1 ratio, the distance for “Y” is 1.5 times the distance of “X.”

When changing the rocker arm’s ratio, you might need to clearance the pushrod holes so there is no interference. We recommend a minimum of .010 inch.

Leave a Reply